WELDING COOLER

INDUSTRIAL CHILLER APPLICATIONS

KEEPING THE PROCESS COOL

IS WORTH IT

Effective cooling is critical to a successful welding operation. Including an industrial chiller as part of your welding operation guarantees cool, recirculating water on demand. Using a water-cooled process chiller during operation increases the duty cycle of your welding equipment. Your equipment can safely run for longer periods of time and reduce costly downtime to allow your welder to cool. Using water cooled equipment also improves the quality of your welds, reduces deformities caused by thermal stress, thus saving valuable resources. Let North Slope Chillers water cool your welding operation and keep the heat in your arc where it belongs.

AN EFFECTIVE WELDING COOLING SOLUTION

Save Time and Money by Avoiding Re-welds

Reduce Weld Deformities

Increase Duty Cycle

Protect Materials and Equipment

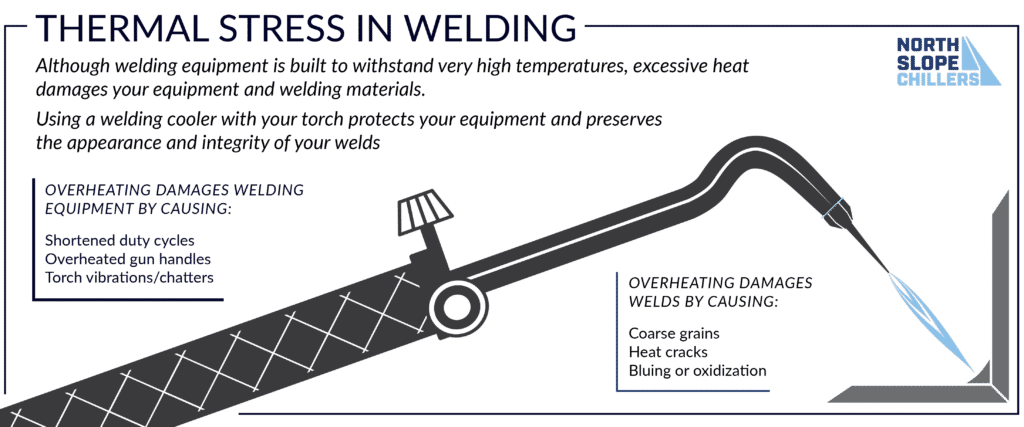

THERMAL STRESS ON WELDING

USING A WELDING CHILLER REDUCES THERMAL STRESS ON YOUR WELDING EQUIPMENT

AND HELPS IMPROVE THE QUALITY OF YOUR WELDS

Heat management will always be an important part of any welding operation. Excessive thermal stress on a weld can cause deformities such as coarse grains, heat cracks, and even bluing or oxidization around your welds. Weld deformities caused by thermal stress are not just a cosmetic issue, but can compromise the strength of your welds and require costly re-welds and repairs. Using a welding cooler with your torch can help reduce thermal stress and improve the appearance and integrity of your welds.

WELDING COOLING SOLUTIONS

Effective welding chilling maintains optimal temperatures and removes thermal stress from your welding torch, which could damage equipment and the integrity of your welds. There are a lot of welding cooling systems on the market. These systems include large overhead fans and air-cooled guns that can be less effective than liquid cooling. Water cooling your welding equipment allows you to operate for longer periods of time without jeopardizing your equipment or safety.

NORTH SLOPE CHILLERS SPECIALIZES IN WELDING CHILLERS

Welding chillers are portable, do not disrupt your current system, and apply direct and even chilling to your process. Welding equipment is a significant investment and North Slope Chillers welding cooling solutions will protect your equipment and optimize performance. Save time, effort, and money with portable welding chillers from North Slope Chillers.