Process cooling can be used almost anywhere, even in the biotech industry! There are many pieces of biotech laboratory equipment that need stable temperatures in order to perform necessary experiments or processes. Additionally, specific materials and samples must be carefully kept at ideal temperatures. Fortunately, there are many options when it comes to process cooling equipment that perfectly meet the needs of biotech applications.

What is Process Cooling?

First, let’s take a look at the basic idea of process cooling. In most process cooling systems, a water chiller is used. In a water chiller, a pump circulates cold water from the chiller, to the process (process: machine/system being cooled). The cool water pumped through the system removes heat from the process. Warm fluid returns back to the chiller and is cooled to start the process over again. This basic concept has been applied in laboratories everywhere to cool, heat, or keep stable temperatures for various products. Now let’s get into the details of specific process cooling systems used in the biotech industry.

Types of Chillers Used in the Biotech Industry

Recirculating Chillers

One type of process cooling used in the biotech industry is recirculating chillers. Recirculating chillers pump water through their systems in order to regulate temperature. The only difference from a basic closed loop system is that recirculating chillers don’t have an internal bath but rather continuously pump water or other fluids through their system. Recirculating chillers are used ideally to cool laboratory equipment -10 to 30°C in 5L. Many recirculating chillers are specifically designed for specific types of laboratory equipment like rotary evaporators, parallel evaporators and extraction products. This is beneficial because these pieces of equipment all must maintain stable temperatures in order to perform correctly. Recirculating chillers allow laboratory equipment to work safely, accuracy, and precisely, and safely.

Immersion Coolers

Another cooling system used in the biotech industry is referred to as immersion coolers. Immersion coolers are used primarily for counter-cooling when connected to a heating circulator. Immersion coolers are also used to rapidly cool fluids down to low temperatures. For laboratories that work with low temperature substances, immersion coolers are perfect. They allow experiements and processess to be carried out at a stable low temperature.

Laboratory Water Bath

Perhaps the most interesting use of process cooling in the biotech industry comes in the form of the laboratory water bath. In this system, a container is filled with heated water. This is used to incubate samples in water at a constant temperature over time. All laboratory water baths have a digital or analog temperature control that allows users to set and maintain their desired temperature. Laboratory water baths are used to warm reagents (reactors in chemical reactions), melt substrates and other substances, or they can be used to incubate cell cultures. Laboratory water baths also allow certain chemical reactions to be more controlled, as they can occur at highly regulated temperatures. Different types of water baths are used for different types of experiments or reactions. For any process occuring in water, the temperature can reach up to 99.9 °C. Anything above 100 °C, would require an alternative fluid to be used like oil, silicone or even sand.

Cooling Chambers

Cooling chambers are used, as you might have guessed it, to cool samples and other substances. Cooling chambers can be used in bakeries to cool entire rooms of bread, and they can be used in chemical storage rooms to ensure safe storage. Cooling chambers allow laboratories to freeze samples, store samples, work with various liquids, and more! This is done through creating a tightly sealed area and using a process cooler to regulate the temperature, as well as using some other chemicals. Cooling chambers use chemicals like nitrogen to allow substances to maintain a colder temperature.

Benchtop Coolers

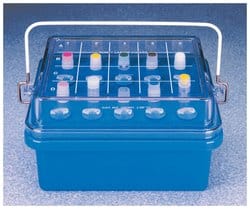

Benchtop coolers are compact enough to fit on most countertops. Benchtop coolers are used primarily to preserve biological samples. Benchtop coolers can maintain freezing conditions longer which allows these containers to stop reactions, store, and transport temperature sensitive materials. Laboratories use benchtop coolers to minimize enzyme, cell, or reagent loss. Benchtop coolers hold standard tube, and vial sizes. Some feature labelled grids or plates to allow users quick identification. Benchtop coolers use ideas from process cooling to regulate temperature. In many cases, benchtop coolers feature some form of insulation that is able to keep the temperature inside very controlled and very stable.

Cooling from North Slope Chillers

North Slope Chillers offers easy to install, portable chillers that won’t disrupt your current setup. If you would like to know more about our product offerings, give us a call at (866) 826-2993 .