Reaching New Lows

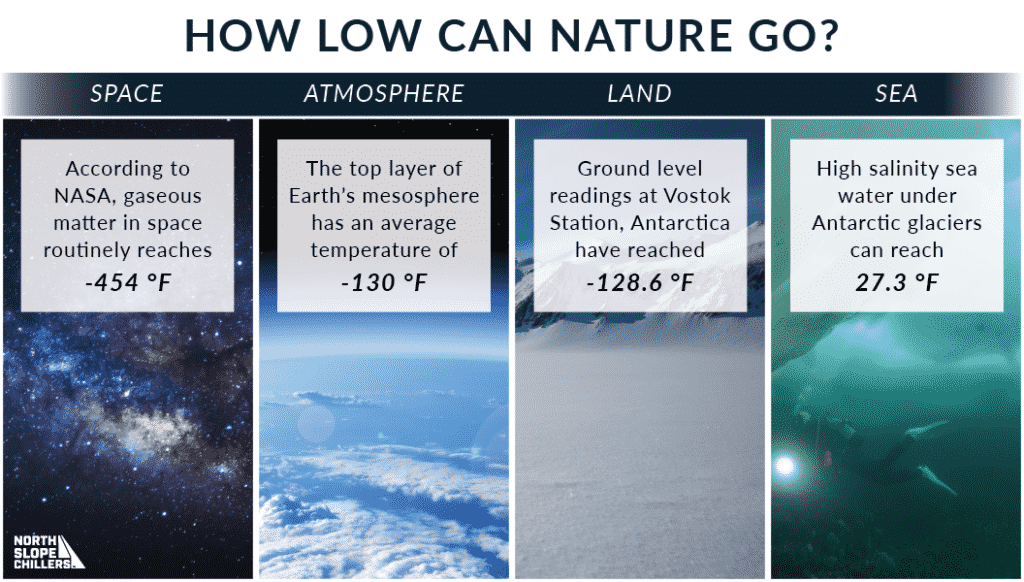

Ultra low temperature process chilling is a highly specialized branch of refrigeration that has a myriad of industrial uses. From aerospace to food service, many industries benefit from pushing the chilling envelope lower and lower. Let’s explore the world of ultra low temperature process cooling.

Ultra Low Temperature Chilling FAQs

What is considered an ultra low temperature?

The ultra low temperature range typically starts at a high of around -40°F (-40°C) and continues to descend from there. Ultra low temperature freezers and chillers can reach a wide variety of low temperatures, depending on the needs of the application.

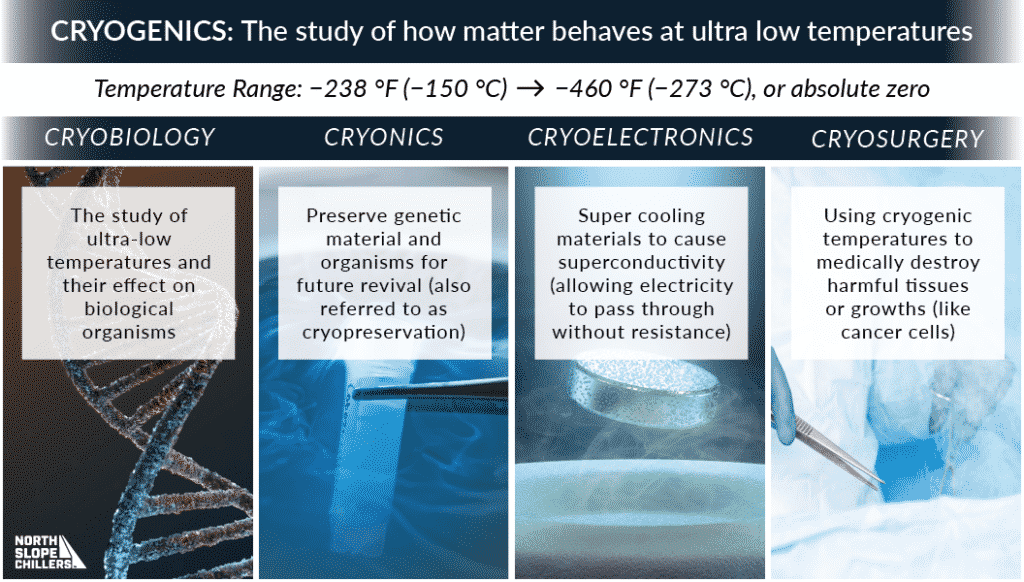

What are cryogenics?

Cryogenics is the study of ultra low temperatures, how they are created, and how they affect matter. The Encyclopedia Britannica classifies cryogenic temperatures as ranging from -238°F all the way down to -460°F or absolute zero. Absolute zero is the theoretical point where molecular motion is as close as it can get to stopping completely.

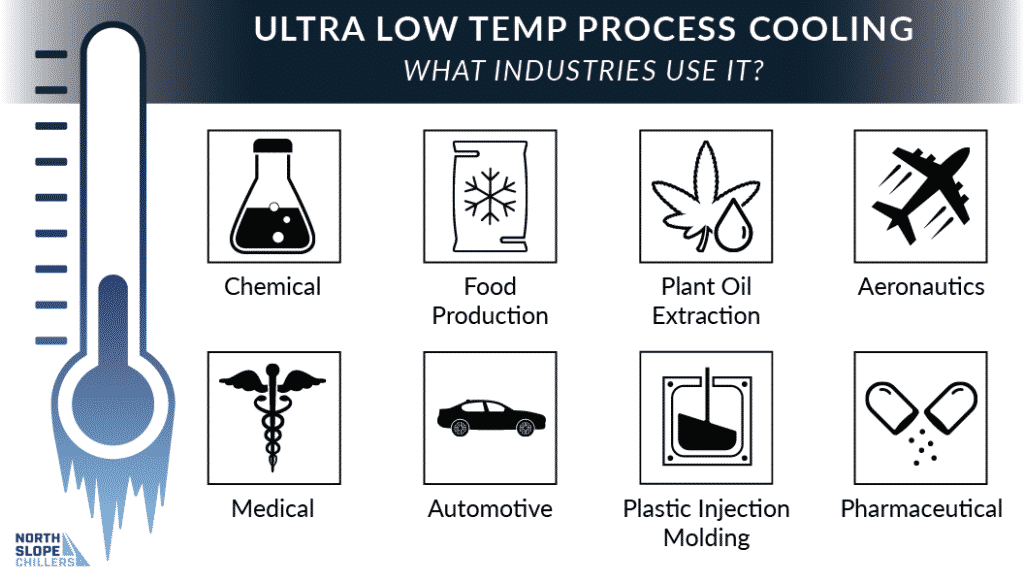

What industries use ultra low temperature chillers?

The uses of industrial low temp chillers are expanding every year. Currently the industries that use ultra low temperatures include: aerospace, medical, pharmaceutical, automotive, defense, plastic manufacturing, chemical, plant oil extraction, food production, and more.

What applications require ultra low temperatures?

Ultra low temperatures are used to: safely store and transport fragile lab samples, temper metals and other materials for extra strength and durability, test materials for use in extreme temperatures/high altitudes/outer space, cool sensitive medical equipment, create superconductors, safely store and transport hazardous chemicals, super chill gasses for plant oil extraction, flash freeze food, and more.

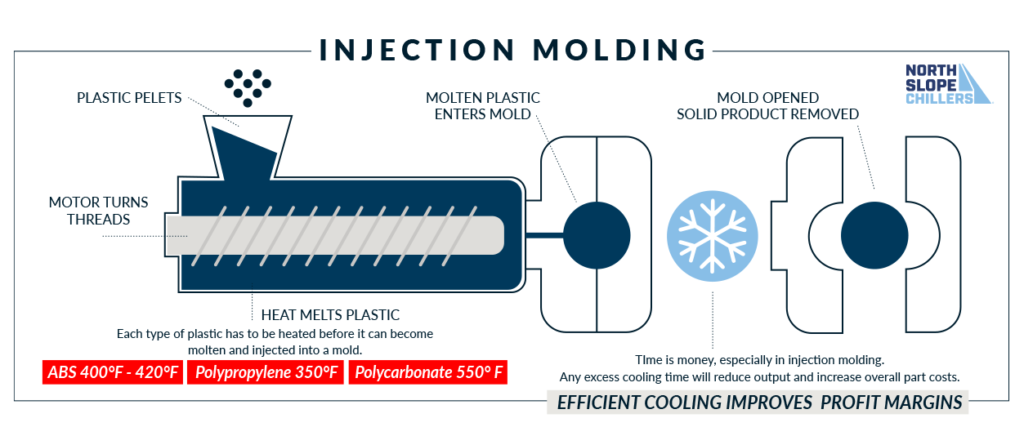

How do ultra low temperature chillers differ from regular chillers?

Regular chillers typically use 1 stage of refrigeration, whereas ultra low temperature chillers can use multiple refrigeration stages. These refrigeration stages can even use different fluids for each stage to reach lower temperature ranges. Ultra low temperature chillers also need more efficient, stronger, and more durable interior components to be able to keep up with the temperature demands. Internal parts (compressor, valves, tubing, pump, etc.) usually need to be upgraded to more robust models for ultra low temperature chilling.

What are the different fluids used in ultra low temperature chillers?

Single stage chillers that operate above freezing temperatures (32°F or 0°C) can use water or deionized water. To increase that cooling range, some single stage or dual stage chillers use a water glycol mix that can achieve even lower temperatures. Below -4° F (-20° C) dual and triple stage chillers can use a variety of heat transfer fluids containing silicone oils, inert fluorinated fluids, hydrofluoroethers, or alkylated aromatic fluids.

What is a recirculating chiller?

Recirculating chillers are closed loop and constantly reuse the refrigerant and process fluids. Heat is either dissipated from the system by forced air or a water cooling tower.

What is a liquid nitrogen chiller?

Liquid nitrogen chillers use containers of supercooled nitrogen that have been chilled enough to change from a gas to a liquid. As opposed to a recirculating chiller (that only expels heat and air), liquid nitrogen chillers expel heat and ventilate gasses. Because the liquid nitrogen is being ventilated, it will need to be replenished, which can make them more expensive to operate than ultra low temperature recirculating chillers.

What is pull down time?

Pull down time is the amount of time it takes for a chiller to descend from the ambient room temperature to the required chilling temperature. Pull down time is affected by the type and amount of insulation, the type of heat transfer fluid used, as well as the efficiency of the compressor.

What should I look for when buying an ultra low temperature chiller?

An industrial ultra low temperature chiller is only as strong as its weakest link. Let’s expand upon this question more thoroughly…

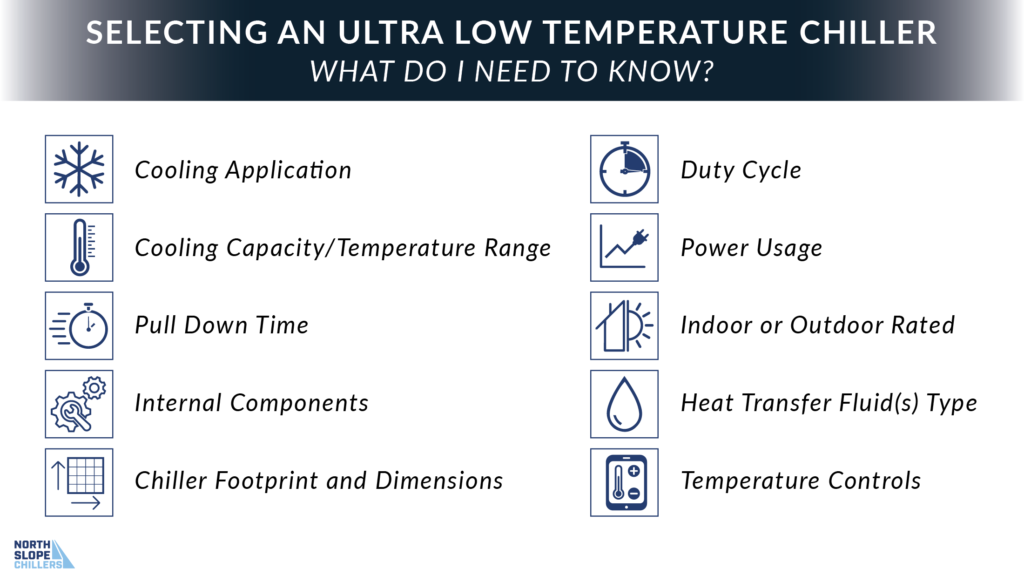

Selecting an Ultra Low Temperature Chiller: What Do You Need To Know?

There are certain questions you need to ask yourself as you start looking for an ultra low temperature solution.

Cooling Application

The very first step is to make sure you thoroughly understand what process or materials you need chilled. This will determine a lot of the specifications you will look for in an ultra low temperature chiller.

Cooling Capacity and Temperature Range

Ask yourself how low you need to go? Be sure to have a really clear idea of how cold you need your chiller to be. It is typically a good idea to purchase a chiller with a slightly wider temperature range than you think you will need.

Pull Down Time

How quickly do you need your chiller to move from ambient room temperature to your desired temperature targets? Some materials are more forgiving than others as they chill, others need ultra cold and they need it fast. Know your chilling timeline so you can be sure the chiller you select will get cold as quickly as you need it to.

Internal Components

Becoming acquainted with the basic interior components of a chiller will help you foresee and avoid future problems. For example: How loud will the compressor be? Is the fluid reservoir made of a corrosive resistant material? Are the interior components rated to work the heat transfer fluid I need? Acquiring a baseline knowledge of a chiller’s inner workings will increase your success in selecting the right ultra low temperature chiller.

Chiller Footprint and Dimensions

Industrial ultra low temperature chillers come in all shapes and sizes. Take a thorough look at your layout and where you need a chiller to operate. Look beyond just the size and fit and make sure your chiller’s vents will be unobstructed so it can operate as efficiently as possible.

Duty Cycle

How long do you need your chiller to operate? Does your application need ultra low temperature chilling 24/7? Or does it need to kick in only occasionally to prevent machinery from overheating? Knowing the answer to these questions will help you pick a chiller that is robust enough for your needs.

Power Usage

For safety and financial reasons, it is extremely helpful to know how much power your chiller will use. This will help you avoid overloading whatever circuit you plug it into. Contact your power company and find out how many cents you will be charged per kilowatt hour in your area. That way you can avoid surprises on your bill after you start using your chiller.

Indoor or Outdoor Rated

Not all ultra low temperature chillers are rated for both outdoor and indoor use. Make sure you know exactly where your chiller will be operating so you can make sure you purchase one that matches its environment.

Heat Transfer Fluid(s) Type

There are a wide variety of heat transfer fluids that can be used to reach ultra low temperatures. Some chillers can have multiple refrigeration stages and use a different fluid or oil in each stage. Do your research on what fluids will help your chiller reach your desired temperature ranges.

Temperature Controls

Thermostatic controls have come a long way in a short period of time. How much control do you want over your chiller? Some ultra low temperature chillers will come with basic controls that require someone to physically input information. Others may come with smart control options that allow you to remotely take control over your temperatures no matter where you are. Would you like to tap into the internet of things and have access to process cooling data analytics? Be sure to look at all of your options and find the solution that will not only fit your budget but will give you the most autonomy and peace of mind.

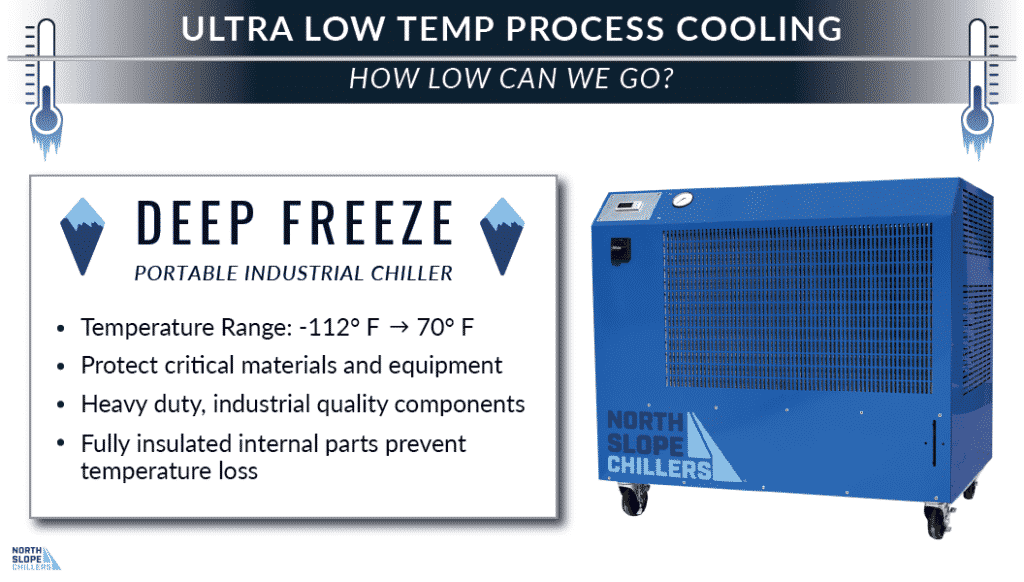

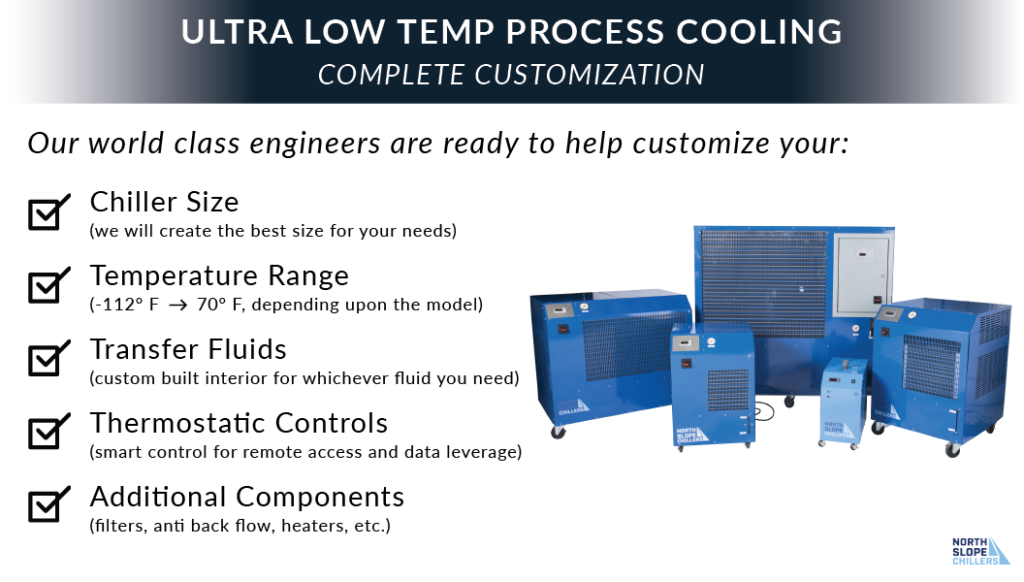

North Slope Chillers Ultra Low Temperature Solutions

Here at North Slope Chillers, we know that one size does not fit all. We are proud to offer the most thorough and quickest customized process cooling options on the market. Instead of searching endlessly for the right chiller, or compromising on some of your requirements, why not custom design the exact ultra low temperature solution you need?

By working with our world class team of engineers you can make sure you find an ultra low temperature chiller that is designed for your exact cooling requirements.

Contact us today to find the perfect ultra low temperature cooling solution for your needs at (866) 826-2993 or [email protected]