Very Cool Tech

Semiconductors are used in just about every computing device we use today. But how do semiconductors work? In order to understand semiconductor devices, we first need to review what a semiconductor is at the atomic level.

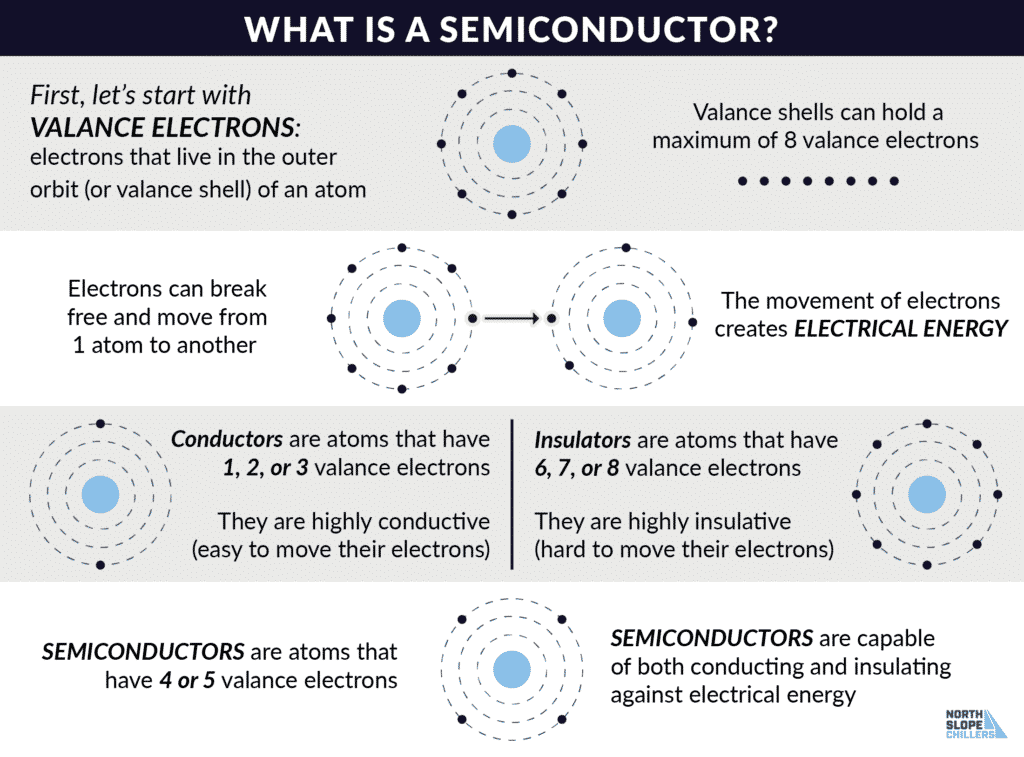

What is a Semiconductor?

First, let’s start with electrons. Electrons live in orbits or shells that surround an atom’s nucleus. The electrons that live in the outermost orbit, or valance shell, are called valance electrons. A valance shell can hold a maximum of 8 electrons. These electrons can break free and move from 1 atom to another, which creates electrical energy. Electrons can be directed to move or flow in a guided direction, creating a flow of electrical current.

Conductors, Insulators, and Semiconductors

When an atom has 1, 2, or 3 valance electrons, it is known as a conductor. These atoms are highly conductive, and it is easy to move their electrons and create electrical energy. When an atom has 6, 7, or 8 valance electrons, it is known as an insulator. It is difficult to break their electrons away, which makes them highly insulative against electrical energy.

Semiconductors are atoms that have 4 or 5 valance electrons. As they occupy the middle of the spectrum between conductors and insulators, you can see that they are capable of both conduction and insulation against electrical energy.

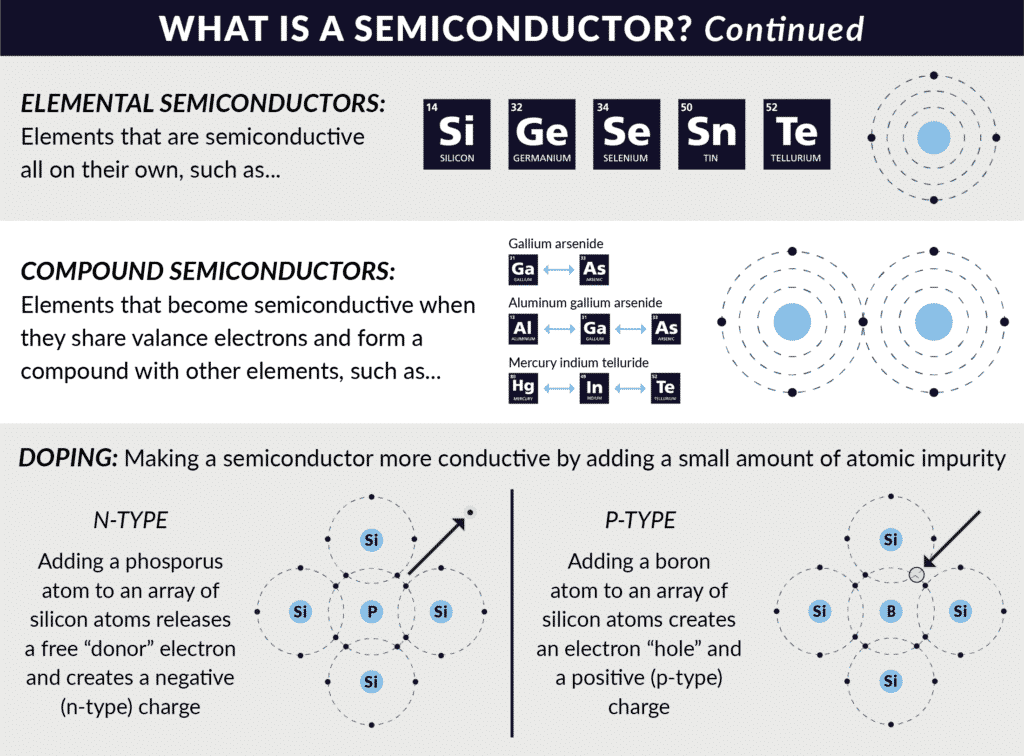

Elemental and Compound Semiconductors

There are some elements on the periodic table that are semiconductors all by themselves, such as: silicon, germanium, tin, selenium, and tellurium. There are however other elements that become semiconductive when combined with other elements. These compound semiconductors include: gallium arsenide (gallium and arsenic), mercury indium telluride (mercury, indium, and tellurium), aluminum gallium arsenide (aluminum, gallium, and arsenic), and more.

Doping

Semiconductors can be made more conductive through the process of doping. Doping is accomplished by adding a small amount (typically 1 part per million) of atomic impurity. There are many elements that are used to dope a semiconductor, but the basic process is the same. When these impurities are added to a host of semiconducting atoms, either a free donor electron is released (creating a negative charge), or an electron hole is created (creating a positive charge).

What is a Semiconductor Device?

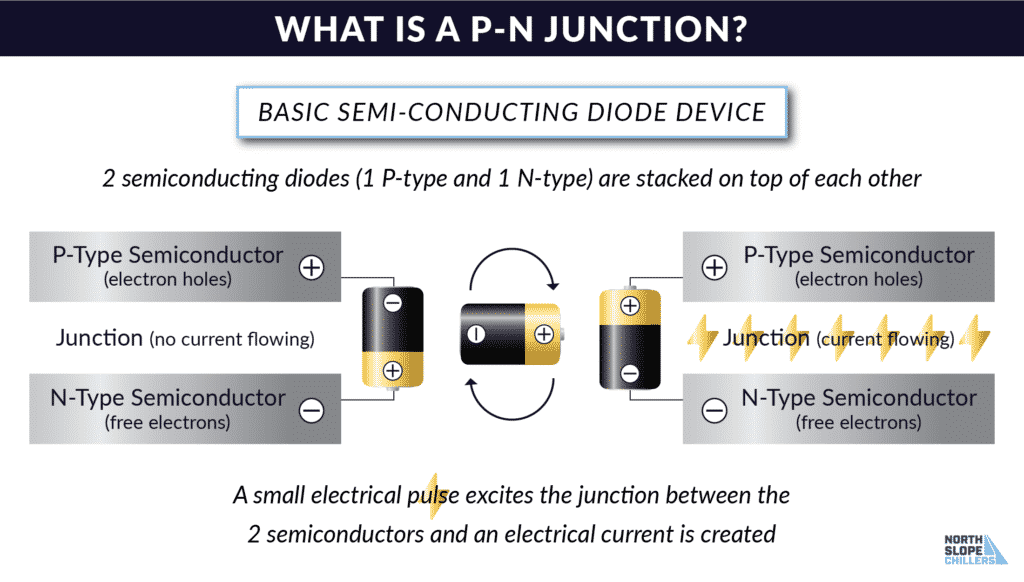

Now that we understand what a semiconductor is on the atomic level, we can take a look at how a basic semiconductor device (like a diode) works. These devices are composed of thin slices of semiconducting material: 1 side is a p-type (positive) semiconductor, the other side is an n type (negative) semiconductor. The space in between these 2 semiconductors is called a P-N Junction. A small electric pulse (like from a battery) excites the junction between these semiconductors and a current is created.

Semiconductor Applications

Semiconductor devices have an infinite number of applications in today’s digital world. Every microprocessor, transistor, resistor, diode laser, and circuit based device is made possible by semi-conductors. These devices vary in complexity based upon how it is used, and what electrical current is required for the application.

Semiconductor Cooling Methods

Truth be told, all electrical currents create some form of heat. As heat builds up within the semiconductor device, it will begin to break down and irreversibly malfunction if waste heat is not removed. Most semiconductors use some form of heat sink that collects the waste heat in 1 location for easier removal. From this point, there are multiple methods of cooling a semiconductor device.

Air Cooling

Some semiconductor devices generate such a small amount of heat, that simple layout adjustments allow natural air flow to remove waste heat. Strategically placed vents facilitate this air flow without the use of fans or forced air.

Other devices need greater air flow velocity in order to remove enough heat to keep a semiconductor device functioning. Forced air has a much greater cooling effect than natural air cooling.

Liquid Cooling

Liquids are an even more efficient method of transferring heat than air. Liquid chillers typically use a mixture of water and glycol to create a heat transferring medium. These fluids are pumped continuously to and from the chiller and the semiconductor device as it is running.

Immersion Cooling

This cooling method involves completely submerging semiconducting devices into tanks filled with dielectric liquid or oil. Dielectric fluids are specialized non-conductive liquids through which no electric current can pass. They can electronically insulate even high voltage equipment and prevent arcing. When this fluid is chilled, it also acts as a liquid coolant for the devices as they continue to operate.

Spray Cooling

The method of spray cooling uses the cycle of evaporation and condensation to remove waste heat. Microjets spray inert fluids at the base of the semiconductor. Heat then transfers into the fluids, causing them to start a cycle of evaporation and condensation.

North Slope Chillers Semiconductor Cooling Solutions

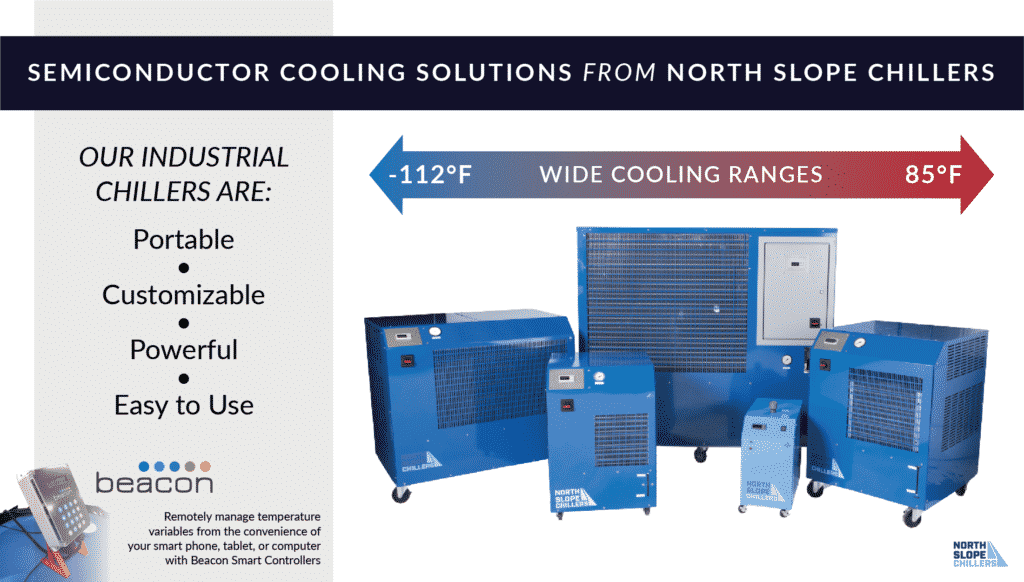

North Slope Chillers’ industrial cooling solutions will cool down your operation without interrupting the layout of your current system. North Slope Chillers provides several levels of industrial water chiller systems, fluid chillers and proprietary chilling accessories to provide precise temperature control that is compact, yet efficient. Easy to install, remove, and relocate, you will be happy to have a fluid chiller unit that is painless and easy to use. Contact us to find the right semiconductor cooling solution for your needs at (866) 826-2993 or [email protected]