Let There Be Light!

Back in 1960, when Theodore Maiman built and demonstrated the first laser, he famously said “a laser is a solution seeking a problem.” They have lived up to that reputation ever since by filling needs in countless industries, and we have barely begun to tap their potential. Let’s look more closely at the types of lasers available today as well as one of the industries most affected by laser technology…manufacturing.

Laser Terms to Know

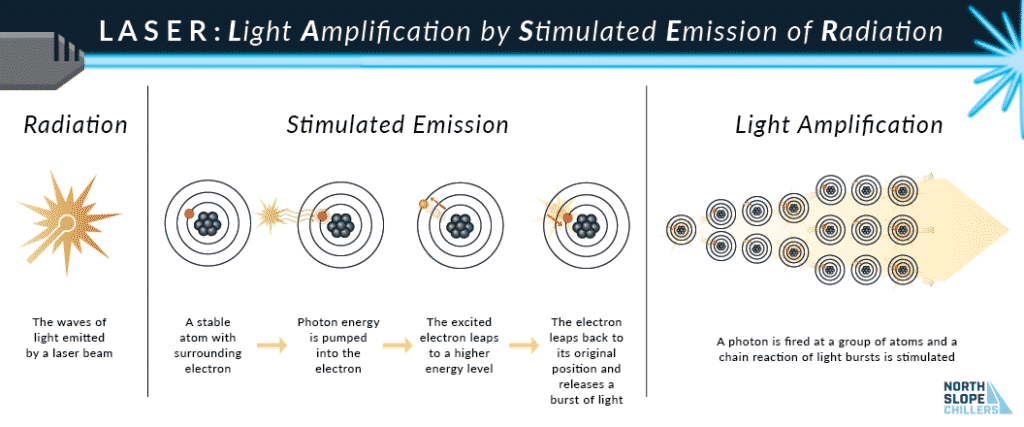

First let’s acquaint ourselves with some necessary laser terminology.

Population Inversion: when there are more atoms within a substance that are in an excited or high-energy state than in a low energy state.

Active laser medium: the substance within a laser whose atoms are stimulated to achieve population inversion.

Doping: Intentionally introducing a small amount of impurities (metal ions) into a laser medium. Allows the atoms within the medium to achieve population inversion.

Types of Lasers

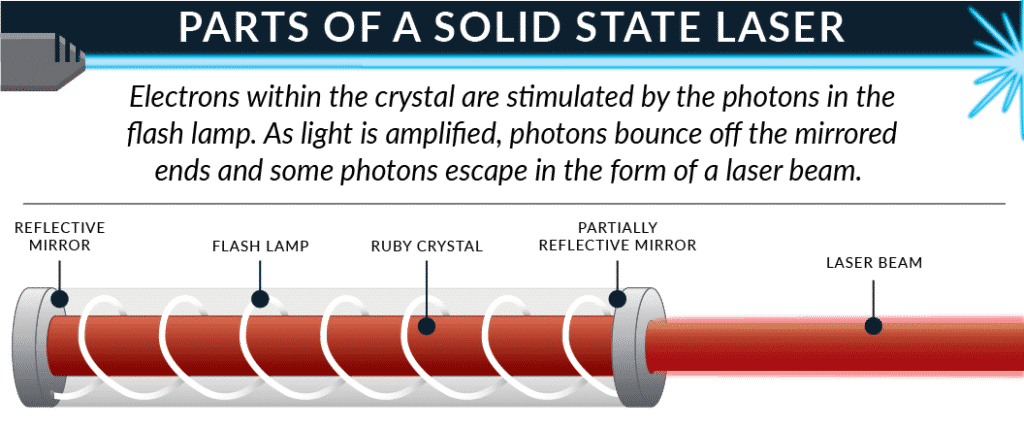

Solid State

Solid state lasers use glass or crystal (ruby, sapphire, garnet, fluorite, quartz) as their laser medium. They are doped with additional metal ions that allow the medium to reach population inversion. The most common solid laser medium today is YAG. YAG lasers use a synthetically made yttrium aluminum garnet. The garnet is doped to become the perfect supportive host for the metal ion, neodymium. Each doped crystal or glass media produces a different wavelength of laser beam. Solid state lasers use small amounts of light energy to create more light. These media are optically pumped with energy from a flash tube, arc tube, or laser diode. Solid state lasers are rugged and simple to maintain.

Liquid

Liquid lasers contain a solution of different types of solutes dissolved in a liquid solvent. The most common type of solute in a liquid laser is an organic dye. The atoms of the dye are the atoms that become stimulated to emit light. Liquid lasers also use flash tubes, arc tubes or laser diodes to pump light energy into the medium.

Gas

Gas lasers use a medium of mixed gases inside a tube. Types of gases used include helium, argon, krypton, xenon, neon, carbon dioxide, carbon monoxide, nitrogen, and excimers (mixture of a noble gas and fluorine or chlorine). Gas lasers convert electrical energy into light energy. Instead of using photons, gas lasers pass an electric current through the gases to produce an excited state.

Semiconductor

Semiconductor lasers are small compact lasers that we encounter everyday. They use a small electric pulse to excite the junction between positively and negatively stacked diodes. Semiconductor lasers are found in everyday items such as bar-code scanners, CD players, dental tools and laser pointers.

Selecting the Right Laser

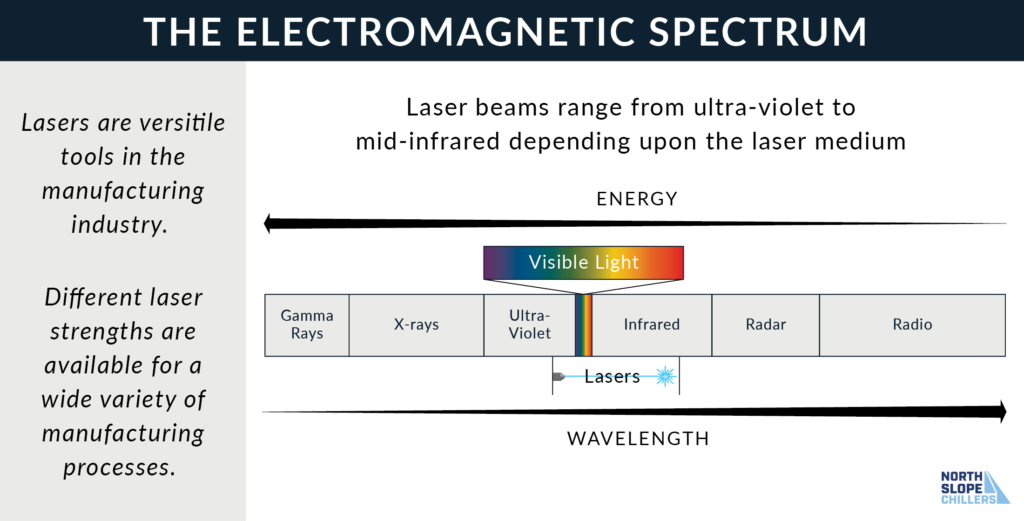

Within each of these laser media, there are many subcategories and that list is growing all the time. Because of this, each of these laser media have a range of power output and wavelengths.

Circuit board manufacturers would likely prefer a laser that operates in the UV range. Other manufacturers that are building engine blocks may need gas or solid state lasers for heavy duty cutting and welding. Manufacturers need to carefully select the right laser medium and power output for their needs.

Manufacturing Uses for Lasers

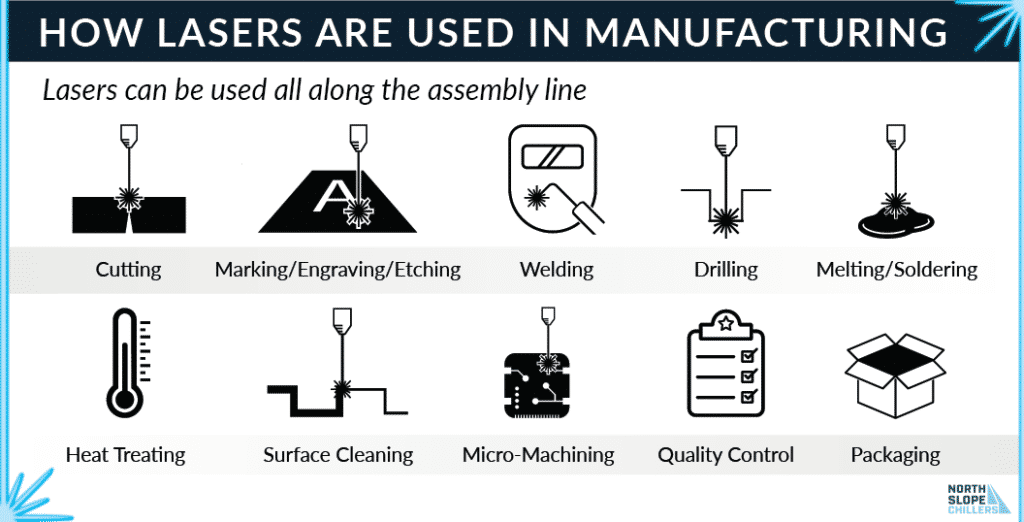

Lasers are re-defining the way we manufacture all the way from design, to production, assembly, and even shipping. They provide manufacturers with precision and efficiency across a vast range of tasks.

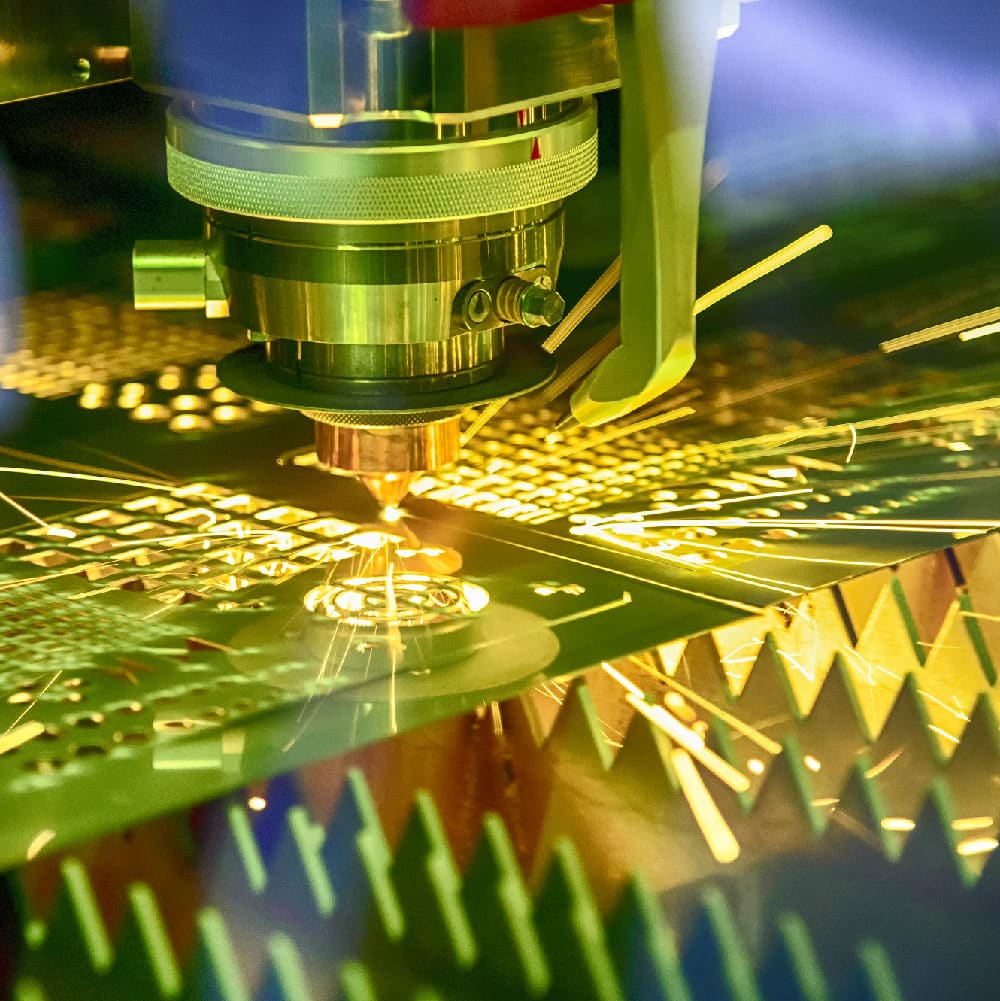

Cutting

Lasers can smoothly cut a huge variety of materials without exerting any mechanical force on the materials being cut. Because no mechanical force is being applied to the material, manufacturers can cut closer together and greatly reduce scrap waste. Touch free laser cutting can easily cut around fine contours and create irregular shapes so industrial designers do not have to compromise their designs in order to make things easier to cut out. Lasers cut so precisely and intricately that they are even being used to create lace. Sheet metal is the most commonly laser cut material, however lasers are also used to cut wood, fabric, leather, foam, acrylic, and more.

Marking/Engraving/Etching

Laser marking involves using a low powered beam to permanently discolor the surface material. This is most commonly used to mark materials with serial numbers, codes, brands, and logos.

Laser engraving cuts away a small portion of the material so that the human eye can see shapes or text on the surface of the material.

Laser etching involves the same process as engraving, but produces even shallower cuts. Etching is most commonly used for small products such as jewelry.

Welding

Lasers are used to fuse together pieces of metal or thermoplastics. Laser welding produces high quality, narrow, and deep welds. Laser welders can also produce less spatter, resulting in cleaner welds.

Drilling

Laser drilling involves pulsing a laser to produce percussion drilled holes. Lasers can pulse and produce holes hundredths of an inch in diameter, or can continue to pulse around larger circumferences to drill larger holes. This process is used on materials as thick and robust as engine blocks as well as tiny circuit boards. Apple uses laser drilling to allow light to shine through metal. Minuscule holes are drilled in specific places in the cases of their tech products that allow light to pass through, but are invisible to the naked eye.

Melting/Soldering

Lasers can be used to melt metallic powders together. These melted materials can then be formed into an endless number of shapes and forms. This process is most commonly used in additive manufacturing and 3D printing. Lasers can also be used in soldering to melt filler metals in bonding items together.

Heat Treating

Lasers can change the micro-structure of certain metals and alloys with specific intervals of laser heating and then cooling. This heat treating makes metals more resistant to abrasions, breakage, and metal fatigue in high performance pieces like engine components.

Micromachining

Because of a laser’s fine precision, they can perform many of the above tasks (drilling, melting, soldering, cutting, marking) on a minuscule scale. Lasers are also used to make machine readable marks on metals, silicon, polymers, and circuit boards.

Surface Cleaning

Lasers can be used to remove unwanted paint and contaminants from certain surfaces (usually metal, ceramic or plastic). Laser stripping is a cleaner and more efficient method than using harsh chemicals and elbow grease.

Quality Control

When mass-producing items that require precise dimensions, lasers can be used to measure and 3-D map difficult angles, curves, and shapes. These lasers can be calibrated to ensure that each product coming off the assembly line is exact and uniform.

Packaging

Lasers are used to scribe, perforate, and mark packaging to make it easier for consumers to open products. Because lasers are capable of fine contouring, manufacturers can create tailor fit packaging for their products.

Lasers and Automation

More and more, these laser tasks can be performed by automation. Robotic arms can be easily outfitted with the appropriate laser for the job and quickly execute pre-programmed functions over and over again. Automated lasers have had the biggest impact on the car manufacturing industry. Car manufacturers are taking full advantage of the precision, cleanliness, and versatility of automated lasers by using them on everything from the chassis, to cutting air bag material, and creating laser cut smart keys.

Protecting An Investment

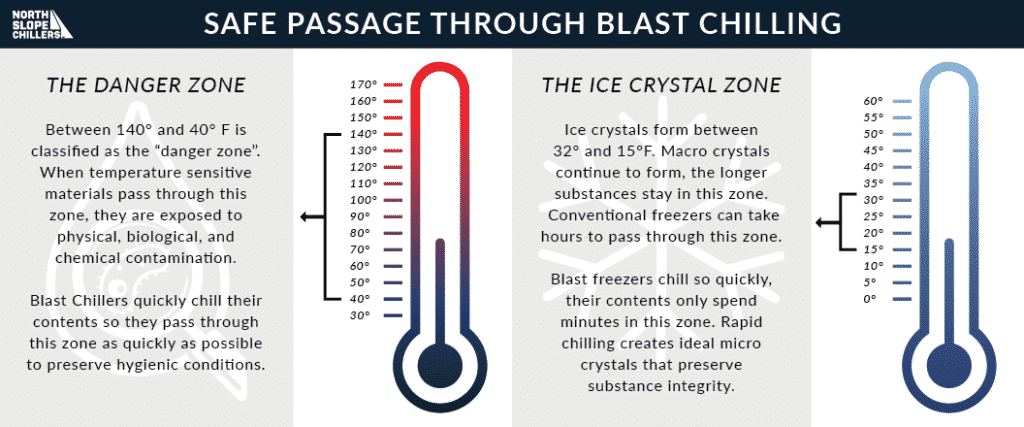

Laser equipment represents a significant investment for any manufacturer. When lasers systems are well cared for, they maintain more precise wavelengths, even power output, and stronger beam quality.

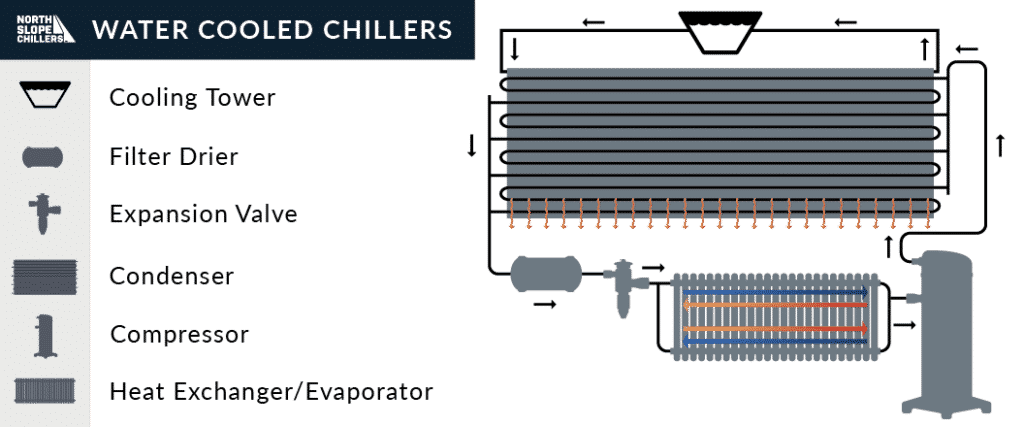

Proper cooling is one of the most important components in increasing the lifetime of a laser system. Reducing laser thermal stress protects both your equipment and the materials being manufactured.

Laser Chilling Solutions from North Slope Chillers

North Slope Chillers industrial laser chillers optimize laser operations and keep systems running efficiently. Chat with a chilling expert to find the best chiller or chilling accessory for your needs at (866) 826-2993 or by email at [email protected].