Epoxy is a go-to material for many industries because it’s strong, waterproof and lightweight. Its uses can essentially be divided into two categories: First, epoxy is often used as an adhesive to permanently bond objects together. Second, epoxy is used to create a lightweight, durable, scratch-resistant coating.

Epoxy and Reactions

Epoxy’s strength and durability comes from the reaction between resins that creates a strong adhesive bond. Epoxy curing is an exothermic reaction. Epoxies that haven’t cured properly generally have poor chemical, mechanical, and heat resistance properties.

Epoxy Curing Time

Epoxy curing time depends on the chemistry of the hardener. Some mixes require just one minute to set. These are best used for small jobs as you won’t have much time to work with the epoxy before it hardens. Other mixes will take much longer. Generally, epoxy that takes longer to set forms a stronger bond. It also gives you more working time.

Factors of Epoxy Curing

While epoxy curing is simple, the factors involved must be carefully addressed for the mixture to properly set. First, the surface or surfaces that will be adhered or coated in epoxy must be properly prepared. Second, the elements of your epoxy mixture have to be properly combined. Next, epoxy application should be smooth and uniform. Finally, and most importantly, epoxy must be cured at the correct temperature.

Heating

The most important factor of heat curing epoxy is maintaining the proper temperature. Improper or uneven temperature distribution can lead to discoloration or color variation, blushing, uneven gloss, brittle product, and poor inner-coat adhesion. Many epoxies cure at temperatures well above ambient air and require a heat source to provide a constant, specific setting temperature. Options include a heat box or oven. For large projects, heat lamps, hot water, or heating blankets can be used. Heating blankets provide the most consistent, reliable solution.

Cooling

Once epoxy has been mixed, the reaction (and curing) begin! While adding heat helps with proper curing, some situations call for colder temperatures. For example, you might need extra time to work with epoxy before it hardens. To keep epoxy from heating up (and hardening) too quickly, it is recommended that you mix your epoxy in a wide, shallow vessel. This creates a wider surface area for heat to escape (remember: curing is an exothermic process). You can also extend work time by keeping epoxy cool or cold while working and then adding heat when you’re ready for it to set.

Storing Mixed Epoxy

If, after finishing a project, you’re left with excess epoxy, it can be stored at cold temperatures to significantly slow or stall the curing process. It is recommended that you keep mixed epoxy stored at around 40°F for no more than a few days. Once you reheat the epoxy, the curing process can resume.

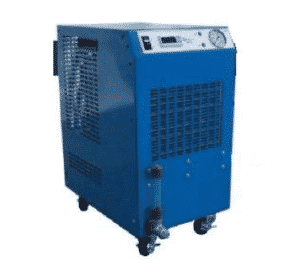

A Solution for Cooling Epoxy

An effective and reliable process cooling solution that can be implemented in the epoxy curing process is the North Slope Chillers injection molding chiller. It’s rated at ambient temperatures from 35º F to 100º F and features a portable design. If you’re interested in producing high-quality epoxy, consider using this chiller to help with total temperature control during the curing process.

Ancient Brewing Meets Modern Technology

Ancient Brewing Meets Modern Technology