Lasers: The Cutting Edge

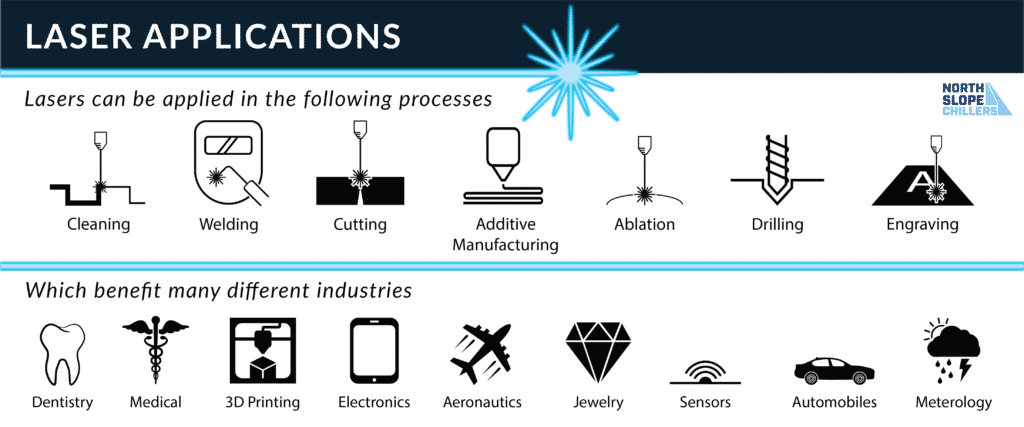

Lasers have fascinated human imagination since they were invented in 1960. Far beyond the realm of lightsabers and Bond villains, lasers have a pivotal role in products and technologies we all use every day.

Types of Lasers

There are many different types of laser medium:

- Solid-State

- Gas

- Excimer

- Fiber

- Disc

- Dye

- YAG

- Semi-conductor/Diode

There are similarities and differences between the different laser mediums, not only in their applications, but in their wavelength ranges, power output, heat output, and cooling needs.

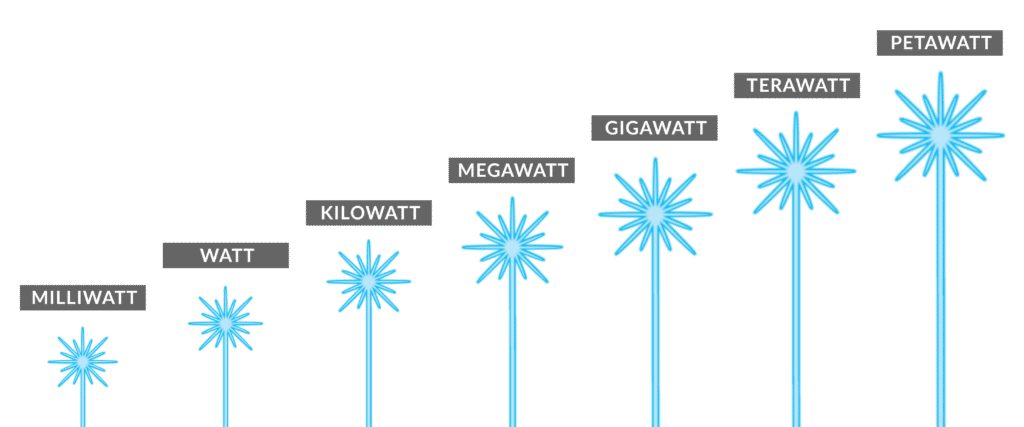

Laser power output spans a very large range:

Low-powered lasers such as those found in laser pointers and disc readers generally have their own built-in cooling system, so they don’t generate enough heat to damage the components surrounding the laser. However high-powered lasers generate a massive amount of heat that must be removed from the laser system.

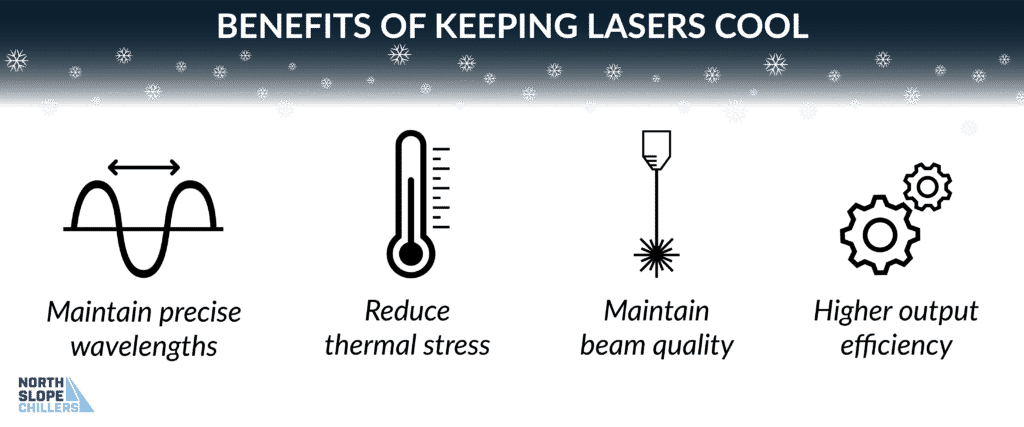

The best method for removing excess heat is using an external industrial laser process cooling system. There are many benefits to keeping a laser system cool.

Benefits of Laser Chillers

Maintaining precise wavelengths

Excess heat in a laser system increases the laser wavelength and compromises the laser’s performance.

High output efficiency

Lasers require very precise specifications in order to perform accurately. An overheating laser can be dangerous, imprecise and make it difficult to point the laser with stability.

Maintaining desired beam quality

Strong beam focus is required for precise laser work such as engraving, cutting, drilling, and printing. A fluctuating beam is dangerous and destructive.

Reducing thermal stress

Reducing the operating temperature can protect materials, equipment, reduce maintenance, and increase the lifetime of the laser system.

North Slope Chillers industrial laser chillers optimize laser operations and keep systems running efficiently.

Chat with a chilling expert to find the best chiller or chilling accessory for your needs at (866) 826-2993 or by email at [email protected].