Put simply, industrial chillers help keep systems and supplies cool. Unwanted heat can cause downtime, wasted materials, slow production, and, consequently, smaller profit margins. Process chillers remove unwanted heat and keep things running smoothly, even when temperatures are high.

Chillers are used in a variety of applications including:

- Process Cooling

- Food and Beverage Production

- Chemicals

- Plastics

- Printing

- Welding

- EDM

- Lasers

Because there are so many options for types of chillers, determining what kind of chiller you need can seem daunting. Picking the wrong chiller can lead to poor results and/or wasted energy and money. Before you make your selection, it’s important to consider your specific cooling needs and to learn about the different types of chillers available.

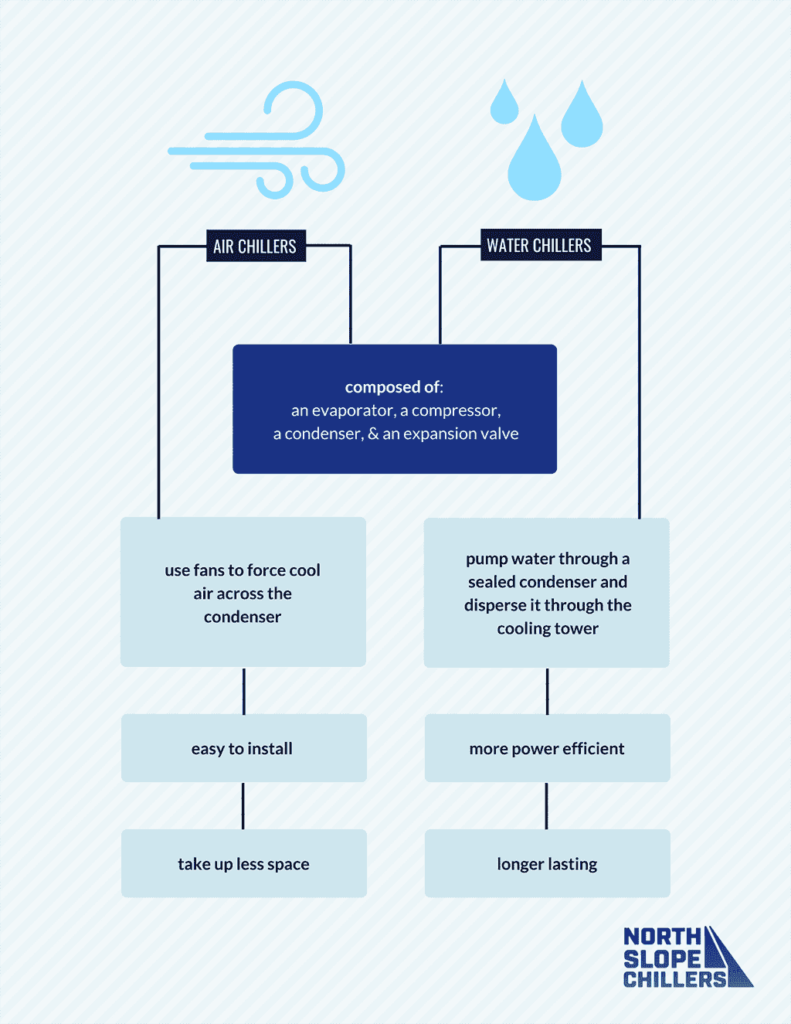

Let’s take a quick look at the two main types of compression chillers:

Air Cooled Chiller vs Water Cooled Chillers

Industrial chillers use either air-cooling or water-cooling technology to operate. There are benefits to both. Your selection between the two will depend on the needs of your operation.

Both types of chillers are made from the same components: an evaporator, a compressor, a condenser and an expansion valve. While the mechanics of moth are fairly similar, air-cooled chillers use fans to move air across the condenser while water- cooled chillers move water through a closed condenser circuit.

Air-Cooled Chillers

Air cooled chillers can typically be installed outside, which means they require no extra interior space. This makes them a great option for stationary cooling. However, it’s important to consider that they require extra energy and are more prone to blockages (compared to water-cooled chillers).

Water-Cooled Chillers

Because water has such a high heat capacity, using water evaporation to dissipate heat is typically much more energy efficient than using air. More often than not, water-cooled chillers will be your most efficient option. Additionally, water-cooled chillers tend to last longer than water-cooled.

North Slope Chillers: Custom Options!

North Slope Chillers offers top-of-the-line chillers sized for several different needs and applications. Our chillers are made to order which means any chiller ordered from us can be customized to fit your exact requirements.

To lean more about chiller selection and to determine which type and size of chillers will best fit your needs, check out our Chiller Selection Guide.