FLUXWRAP

FLUID CHANNEL BLANKETS

PERFECT

PARTNERS

Fluxwrap™ can chill materials in drums, totes, tanks and all manner of vessels, even when a heat exchanger is not currently present. The proprietary, multi-channel fluid path allows maximum flow of the cooling liquid with minimal pressure. The wrap conforms to the container shape and maintains thermal contact over uneven surfaces–creating full coverage cooling. Do you have a need for cooling and heating? Simply change the temperature of the Fluxwrap™ fluid, and you have an effective medium for heating. Fluxwrap™ is a versatile fluid temperature control solution.

CLICK BY MODEL TO LEARN MORE

FLUXWRAP FEATURES

Proprietary multi-channel fluid path allows maximum flow with minimal pressure

Elastic strap design ensures good thermal conductivity between blanket and drum

Wrap conforms to drum or tote to maintain thermal contact over uneven surfaces

Lightweight compact design

Ideal for process cooling, and industries looking to control high temperatures.

Full coverage cooling

Comes standard with insulated wrap for thermal control and to reduce condensation

Draw heat away from the container and lower the temperature of the contents within.

OUR FAVORITE ACCESSORY

Fluxwrap by North Slope Chillers is a convenient and simple temperature solution that’s not afraid of double-duty. Whether you seek to heat or cool, liquid circulates through Fluxwrap, regulating the temperature of your containers and equipment and providing consistent temperature control.

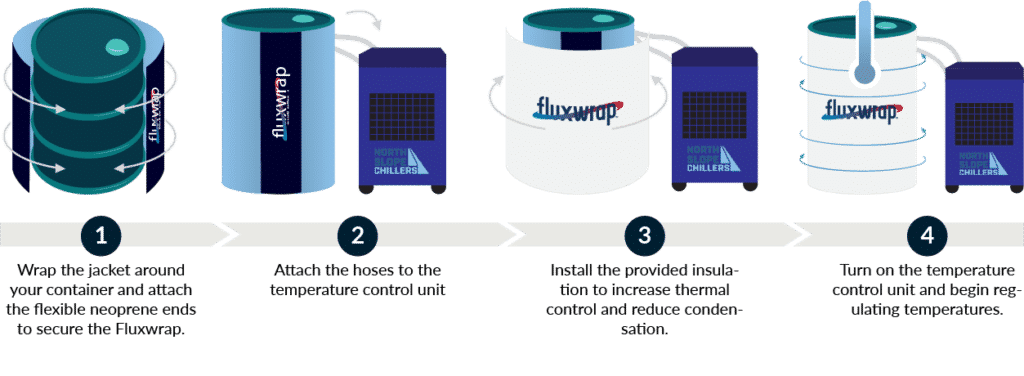

USING FLUXWRAP IS SIMPLE

COLD

FLUXWRAP DOES DOUBLE-DUTY

HOT

North Slope Chillers’

Favorite Accessory

Fluxwrap by North Slope Chillers is a convenient and simple temperature solution that’s not afraid of double-duty. Whether you seek to heat or cool, liquid from your compact chiller unit circulates through Fluxwrap, regulating the temperature of your containers and equipment and providing consistent temperature control.

AIR LIQUIDE

FLUID TEMPERATURE CONTROL

HAZARDOUS LOCATION HEATERS THAT NEARLY DOUBLED DAILY OUTPUT

Air Liquide moves dichlorasaline gas from 1 ton cylinders to smaller, portable containers for distribution. The major hurdle they faced came as the gas became too cold in winter and cold conditions, preventing the container from draining completely. Ideally, this gas needed to maintain a regular temperature of 120° F to flow correctly in the winter. Read on to see how North Slope Chillers helped so solve this dillema.