What are cannabis extracts and what are they used for?

The goal of cannabis extraction is to create a product with a high concentration of cannabinoids. Cannabis extracts come in different forms including powders, rosins, and oils and are believed to have powerful medicinal properties.

Cannabis Extraction

The goal of cannabis extraction is to generate a high-concentrate cannabinoid (the active ingredients in cannabis) product for potential beneficial use.

Timothy Welty, chair of the department of clinical sciences at Drake University’s College of Pharmacy and Health Sciences, in Des Moines, Iowa, explains that “CBD (a cannabinoid found in cannabis plants) is kind of a tricky drug because it’s not very well absorbed orally. Less than 20 percent of the drug is absorbed orally. If it isn’t made in the right way, you may not be getting much drug into your systemic circulation.”

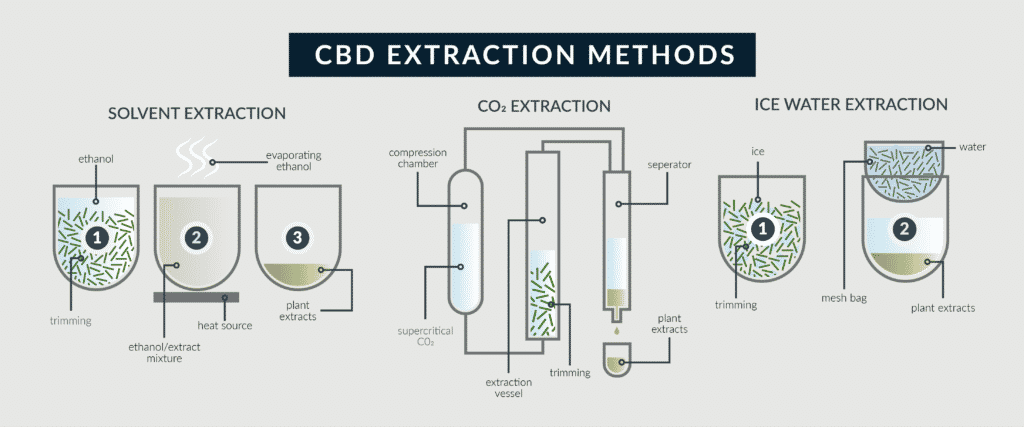

Common Cannabis Extraction Methods

There a few different methods employed when extracting active ingredients from cannabis plants. Here are a few of the more common methods:

Solvent Extraction

For this method, cannabis trimmings are steeped in ethanol. The ethanol is evaporated, leaving the plant extracts behind.

CO2 Extraction

This method is extremely technical but yields the most potent results. Supercritical CO2 passes through plant trimmings, dissolving the extracts. The extracts are then separated from the CO2.

Ice Water Extraction

This method results in what’s most commonly referred to as “Bubble Hash”. Cannabis trimmings are mixed with ice. Water is added and the mixture is strained through several layers of mesh.

(For more details on cannabis extraction methods, check out this blog article. )

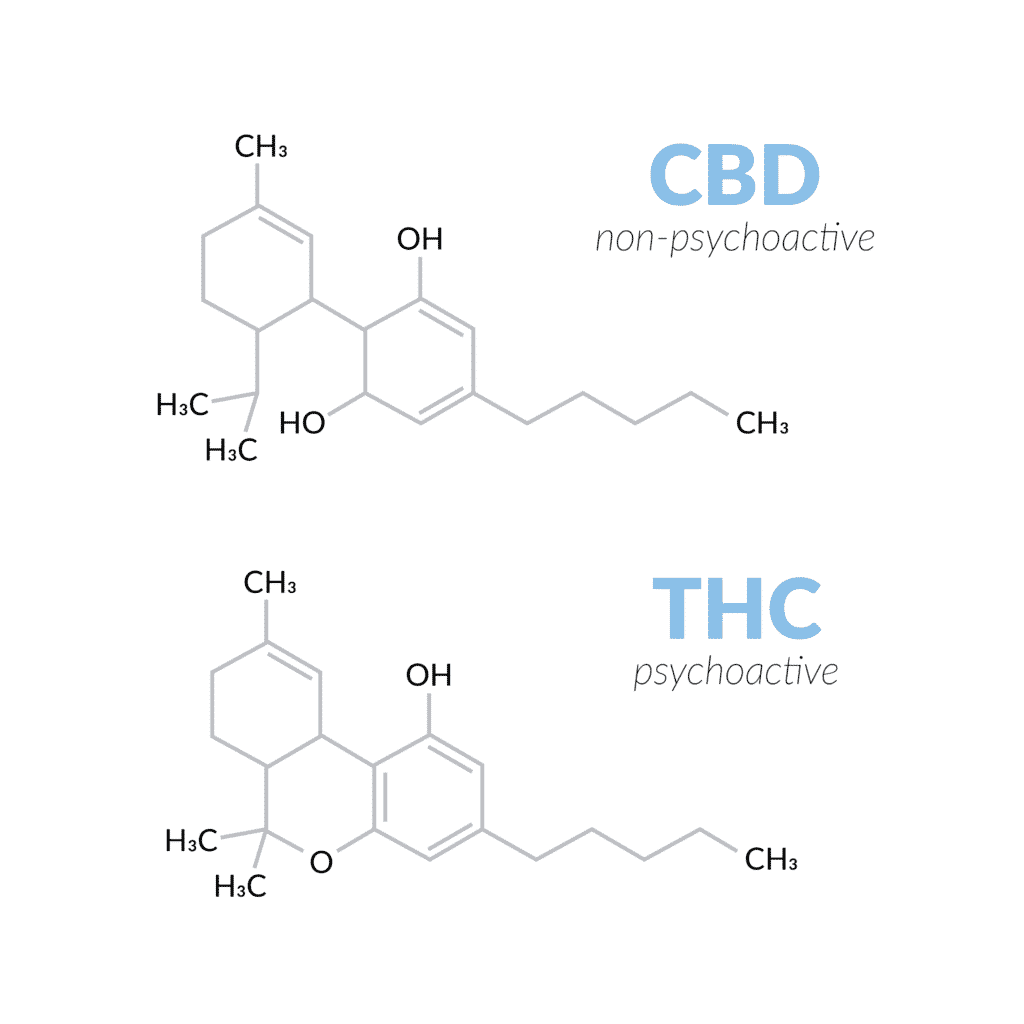

THC vs CBD

Quality cannabis extracts contain a high concentration of cannabinoids. The two main players when it comes to cannabinoids are tetrahydrocannabinol (THC) and cannabidiol (CBD). Put simply, THC is what gets you “high” while CBD is often sought after for its claimed medicinal properties.

THC

Tetrahydrocannabinol (THC) is the most potent psychotic found in cannabis plants. As mentioned above, it’s found in higher percentages in marijuana. Besides giving you a “high,” THC can cause feelings of lethargy and dysphoria and may even make anxiety and seizures worse.

CBD

Cannabidiol (CBD) does not have intoxicating effects like THC. CBD oil is often used to treat epilepsy and pain. Some claim that CBD relives sleep issues, depression, anxiety, and other mental health disorders. It may even counteract the psychoactive effects of THC. CBD usage has been linked with side effects like decreased appetite, fatigue, weakness and sleeping problems.

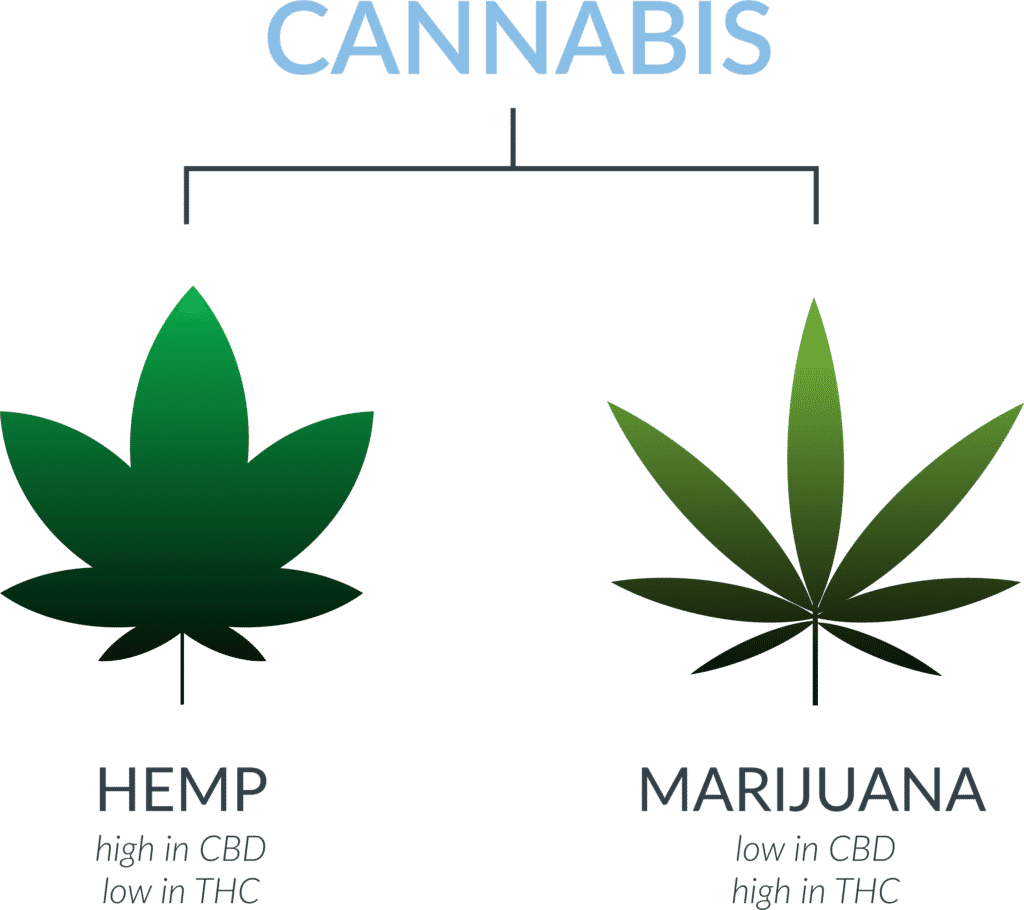

Hemp vs Marijuana

All cannabis extracts start with a cannabis plant. While the terms cannabis, marijuana and hemp are often used interchangeably (i.e., CBD oil is often referred to as marijuana oil) , if you want to understand cannabis extracts, it’s important to know the difference between the three.

Cannabis is a family of plants. Marijuana and hemp are two different types of plants that fall under the umbrella of cannabis. While marijuana typically has a higher percentage of THC, hemp usually has a higher percentage of CBD

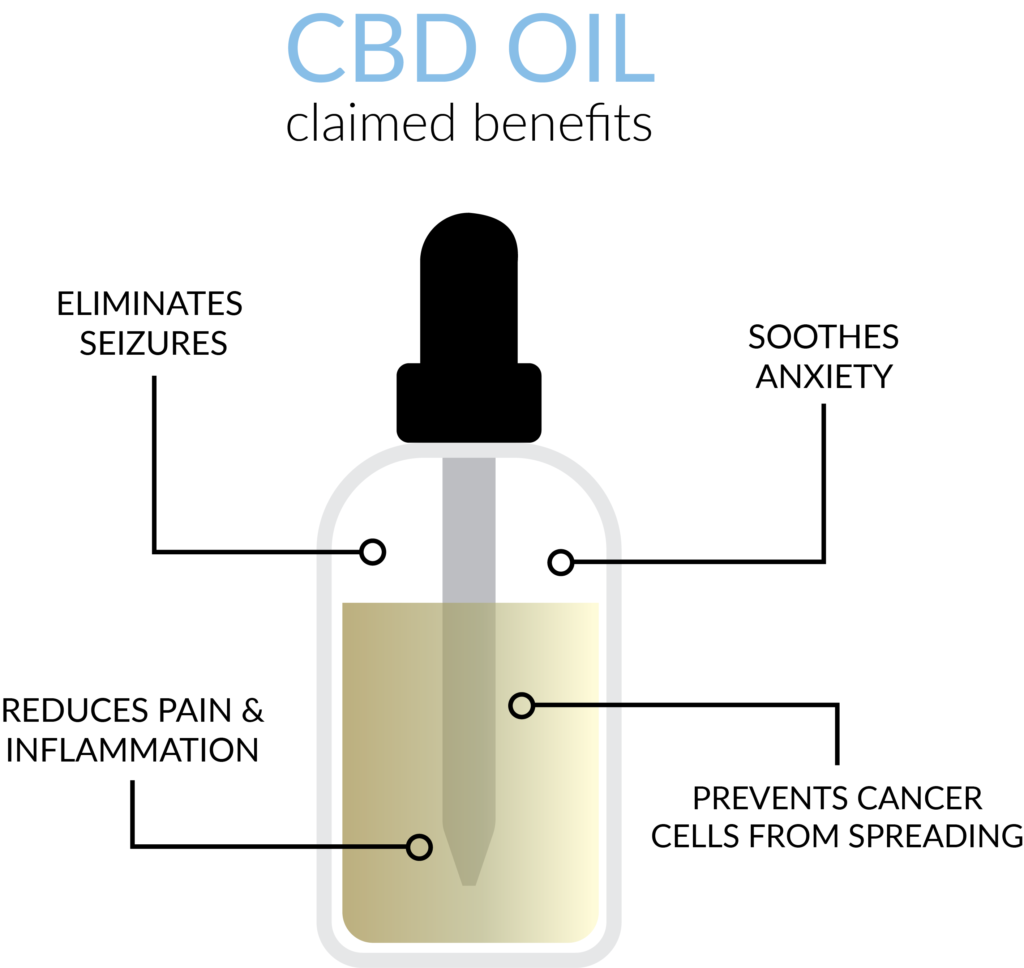

Common Uses for Cannabis Extracts

Research on the benefits of cannabis extracts is limited. Studies, however, have indicated that extracts, specifically CBD oil, can help with the following symptoms and diseases:

Epilepsy

Epilepsy is the only condition with significant scientific evidence that supports CBD as a viable treatment option. Three separate clinical trials have indicated that pharmaceutical-grade CBD reduces seizures with minimal side effects. The CBD-based medication Epidiolex is currently used to treat two rare forms of epilepsy: Lennox-Gastaut syndrome and Dravet syndrome.

Pain/Inflammation

While there hasn’t been enough human trials to confirm CBD’s effect on pain and inflammation, animal trials indicate it could be a successful treatment. Some research has found that CBD reduced levels of chronic inflammation in rats and mice.

Anxiety

Some human clinical trials suggest that CBD could be an effective treatment for anxiety disorders including generalized anxiety disorder, panic disorder, social anxiety disorder, obsessive–compulsive disorder, and post-traumatic stress disorder.

Cancer

An article published in the British Journal of Clinical Pharmacology that CBD can prevent cancer cells from spreading. While more research is needed to further support this claim, CBD’s anti-cancer properties are currently being researched throughout the United States.