Built To Blast

When a refrigerator is opened, warm ambient from the room enters and the temperature inside the refrigerator increases. Once this happens, the fridge’s compressor activates to re-cool the air inside. Domestic fridges are designed to withstand being opened from time to time and still protect the contents inside. However, certain industries require chilling solutions with a lot more power. Let’s take a look at the power behind blast chillers.

What Are Blast Chillers?

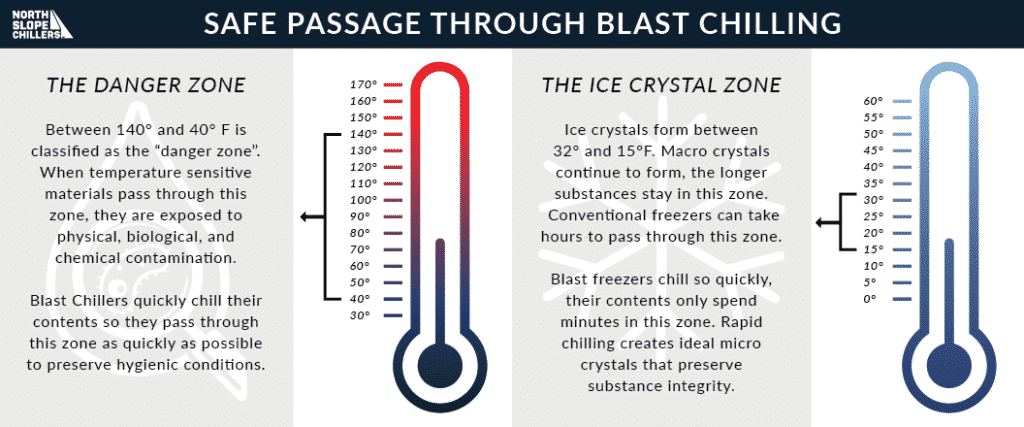

Blast chillers are high powered refrigeration or freezing units that chill faster than traditional cooling methods. Rapid chilling brings foods, beverages, and other temperature sensitive substances through the pathogen growth zone as quickly as possible. Blast chillers vary greatly in size and set up. Some are built to allow large wheeled racks to be rolled inside, other smaller models can be stored under counter tops for easier access.

What Are Blast Chillers Used For?

Food Preparation

The Food and Drug Administration (FDA) follows Hazard Analysis and Critical Control Points (HACCP) to prevent biological, physical, or chemical contamination. These hazard control points address not only proper temperatures but the time frames required for chilling foods and beverages. Any company that processes, stores, transports, or sells food and beverages is legally required to follow these guidelines.

In the restaurant industry, kitchen staff often need to prepare food ahead of time to get ready for meal rushes. Certain food items can be pre-cooked, blast chilled, easily reheated, and still maintain their taste, texture, and freshness. Blast chillers are effective enough that chefs can move food straight from their heat source to the chiller.

Prepackaged food products sold in grocery stores are often blast chilled before being shipped. Foods that are rapidly cooled, maintain their color and cellular structure so they look and taste like they were just prepared for the first time.

Laboratory Research

Maintaining cell structural integrity is also very important in laboratory research. Lab researchers use blast chilling to preserve specimens and chemical reactions. Blast chilling is an important step in protecting sample viability during storage and transportation. Slow cooling produces large and destructive ice crystals that can damage cell membranes and compromise research.

How Do Blast Chillers Work?

As mentioned above, every time a chilling container is opened, the internal temperature rises. Chillers inside busy commercial kitchens and laboratories are in constant use, and need powerful compressors to quickly replace chilled air and preserve hygienic conditions.

In addition, blast chillers also require higher velocity fans to maintain a continuous circulation of icy cold air. Some blast chillers are even equipped with rounded internal corners to assist with cold air circulation. The combination of more powerful compressors and fans prevent contamination from developing.

When temperature sensitive materials need to be frozen, blast freezers provide the same hygienic rapid cooling, but at sub-freezing temperatures. Gradual freezing creates large macro ice crystals that can rupture cell membranes and cause irreparable damage. Blast freezing creates less destructive micro ice crystals that preserve the the quality of the substance being frozen.

Cooling Solutions From North Slope Chillers

Proper temperature control is crucial in the food service and research industries. North Slope Chillers specializes in products designed to preserve hygienic conditions. Contact North Slope Chillers today to find the right temperature control solution for your needs:

(866) 826-2993 [email protected]