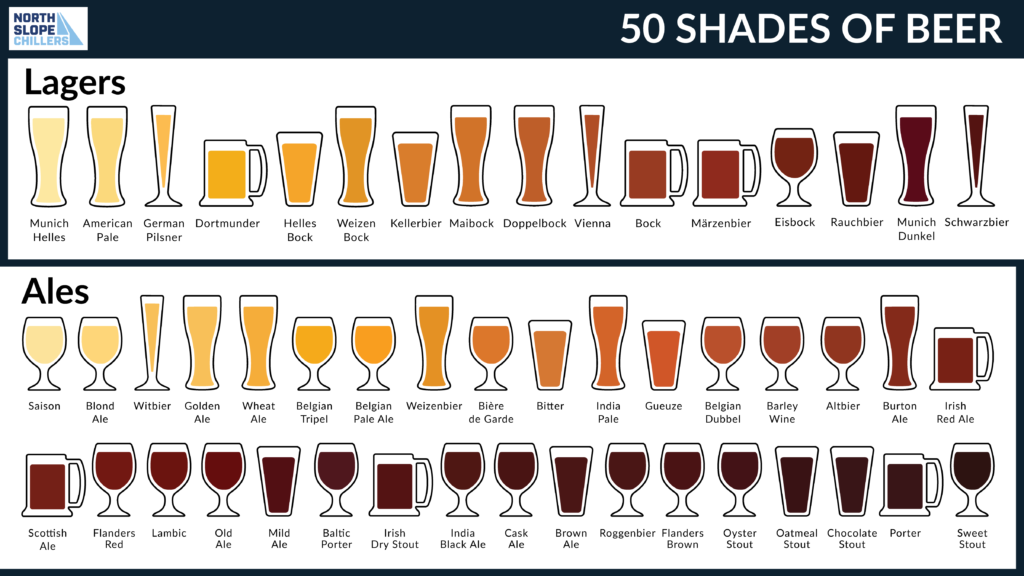

50 Shades of…Beer

When handed a glass of beer, first look, then taste. Let your eyes drink it in before your taste buds. Taking a moment to experience the colorful visual appeal will enhance the experience. Let us explore the science behind the art of beer color.

The Color of Chemistry

The beer color spectrum contains a wide variety that range from pale yellow to jet black.

Color and appearance have a huge influence on which beer selection is the most appealing to various consumers. So how are all these colors produced?

There are many different factors that can influence the overall color and clarity of a brew. Some of these factors include:

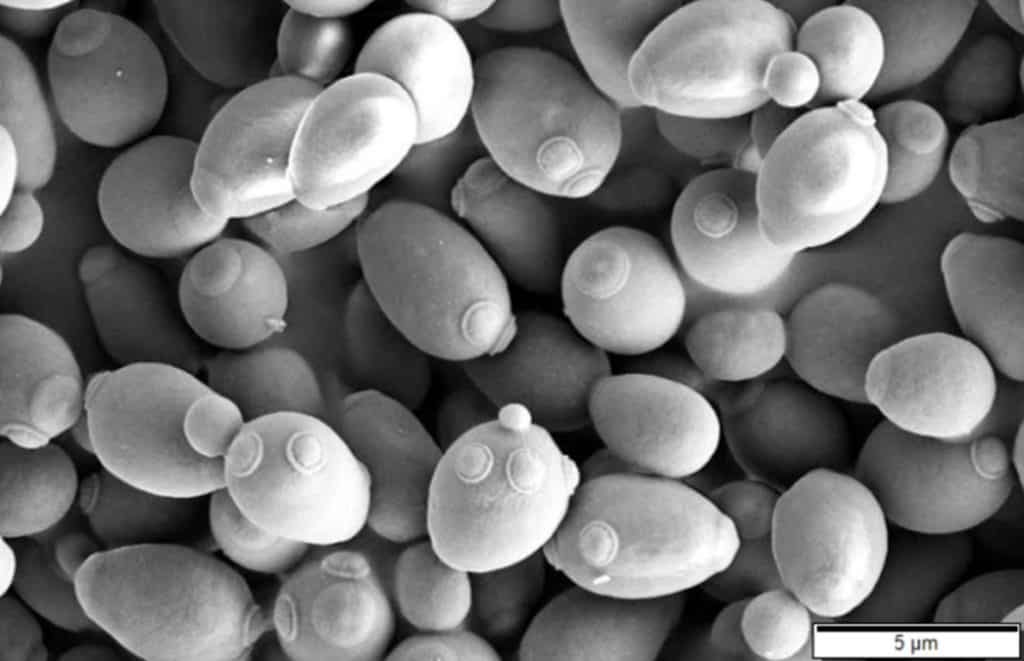

- yeast strain

- filtration

- aging time

- pH level

- oxygen level

- hops variety

- wort chilling

- specialty ingredients

The factors that have the biggest impact on color variation are the chemical reactions that occur during the malting process.

There are 2 types of chemical reactions that affect final brew color:

The Maillard Reaction

The Maillard Reaction is a chemical process between amino acids and sugars that gives browned foods their specific flavor. Searing steak and toasting bread are examples of food experiencing the Maillard Reaction. Roasting grains during the malting process affects the darkness of the malt, darkness of the beer, overall taste, and aroma.

Caramelization

Caramelization is a chemical reaction that involves the browning of sugars and can occur during boiling in the malting process. The longer the boil, the darker the color of the finished beer. This process can produce sweet and buttery flavors and aromas.

Measuring Color

Through the ages categorizing beer colors has changed and become much more scientific and precise. Previous color measuring methods, such as the Lovibond scale, compared beer to pre-set color samples. However, this method relied too much on the visual appearance of beer and could be compromised by human error such as color blindness. Brewers now have a much more precise method for measuring the wide range of subtle color options for beers, known as the SRM.

What is SRM?

The Standard Reference Method is the finished beer and malt color measurement system adopted by the American Society of Brewing Chemists (ASBC) since 1950. This method uses a spectrophotometer to measure the absorption of a specific wavelength of light through 1 cm of beer. Other brewing agencies such as the European Brewing Convention have also converted to measuring light absorption as well.

Let North Slope Chillers help you perfect your brew across the whole spectrum. Portable fermentation chillers from North Slope Chillers can keep your ingredients and equipment at optimal temperatures throughout the brewing process with very little effort.

Contact us to find the right fermentation chilling solution for your needs:

(866) 826-2993 or email us at [email protected]

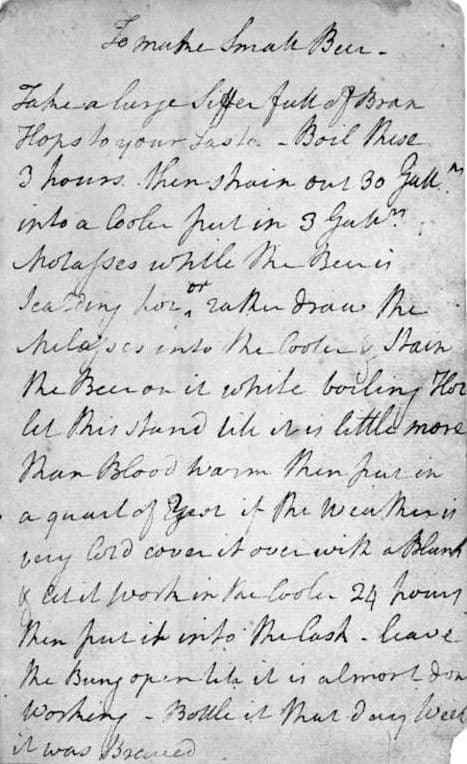

Ancient Brewing Meets Modern Technology

Ancient Brewing Meets Modern Technology