Save Your Data And Beat The Heat

Server rooms and data centers are the lifeblood of any technology company. The equipment in these rooms generate very high levels of heat and must be carefully climate controlled. Excessive heat in a server room damages valuable equipment, jeopardizes communication networks, and causes data loss and costly downtime.

According to IBM, the recommended temperature for a server room is 72° F, with 45% relative humidity. Servers can tolerate temperatures in a range outside that goal (60° – 90° F), however operating with those optimum conditions in mind keeps you better prepared for unintended heat spikes.

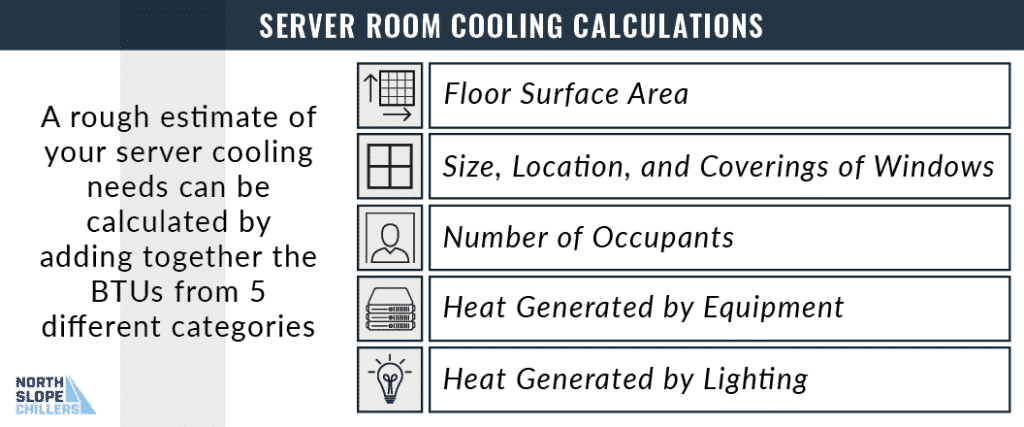

Calculating Heat Load:

The amount of heat a server generates is known as heat gain or heat load. The heat load inside a server room is influenced by 5 different factors:

- The floor surface area

- The size, position, and coverings of the windows

- The number of room occupants

- The heat generated by equipment

- The heat generated by lighting

You can pull together a reasonable estimate of your cooling needs by using the following calculations.

Floor Surface Area

Length (m) x Width (m) x 337 = Room area BTUs

Window Size and Position

If there are no windows in your server room, proceed to the next calculation.

For Southern Hemisphere, reverse the formulas.

South facing window length (m) x south facing window height (m) x 870 = south facing window BTUs

North facing window length (m) x north facing window height (m) x 165 = north facing window BTUs

If the windows have no coverings multiply the window BTUs by 1.5

Add the window BTUs together:

South facing window BTUs + North facing window BTUs = Window BTUs

Occupants

Number of occupants x 400 = Occupant BTUs

Equipment

The wattage listed on a piece of equipment is its maximum power output, but it is better to overestimate rather than under estimate.

Add together the wattage for every piece of equipment: servers, routers, etc.

Total wattage for all equipment x 3.5 = Equipment BTUs

Lighting

Add together the wattage for every light fixture.

Lighting wattage X 4.25 = Lighting BTUs

Total Heat Load = room area BTUs + window BTUs + occupant BTUs + Equipment BTUs + lighting BTUs

These calculations can give you a rough guide to your cooling needs. A cooling audit of your server room will provide you with the most accurate information.

Keeping Your Server Room Cool

Residential AC units generally cannot run 24/7/365 without breaking down, and are not a reliable solution for server room cooling.

Re-designing the layout of your server room to accommodate bulky, built in cooling units is expensive and disrupts the usability of your servers. Strategically placing portable server coolers is an easy way to remove heat exactly where it needs to be removed.

North Slope Chillers Solutions

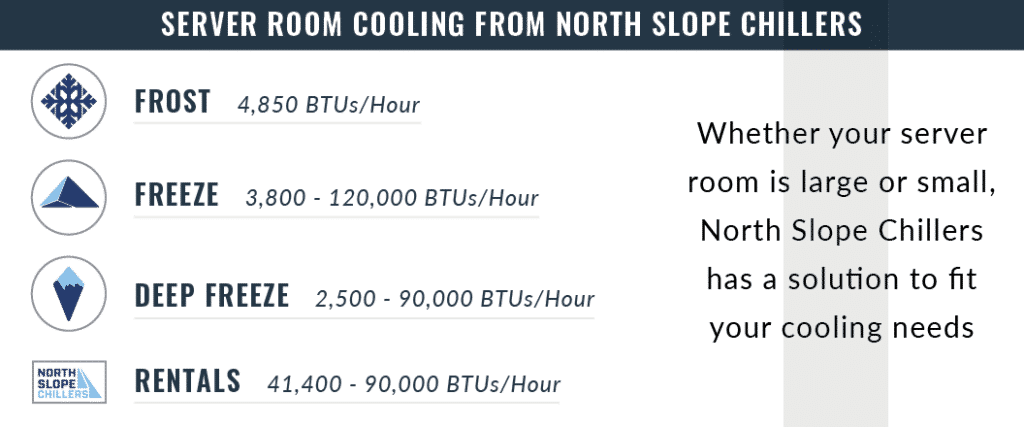

Portable server coolers from North Slope Chillers have a wide range of cooling capacities.

Contact us to find the right server cooling solution for your needs:

(866) 826-2993 [email protected]