Process cooling has a place in many industries, and is no stranger in the world of dairy production. What role do dairy and milk coolers have in getting milk ready for consumption?

Process Cooling in the Dairy Industry

The dairy industry is massive, with $38.1 billion of milk produced in the United States alone in 2017. As a part of that industry, pasteurization is critical to producing milk for consumer use. Pasteurization kills and removes harmful bacteria from milk liquids. Process cooling controls temperatures during and following pasteurization procedures.

Bacteria

As it leaves the animal, milk is inhabited by harmful pathogens, and is generally unsafe to consume. According to Milk Facts, some of these bacteria include:

- E. coli: One of the most infamous bacteria, E. coli in most of its strains is harmless and used by the human digestive system. However, E. coli strain O157:H7 is a different matter. This particular strain produces toxins that can make humans sick, even leading to death in some cases. Thankfully, pasteurization kills the O157:H7 strain.

- Listeria monocytogenes: This bacteria can infect nearly anyone and is regularly found in unpasteurized milk. Symptoms found in humans that have contracted Listeriosis range from fever and muscle aches to stillbirths and death. Though pasteurization kills Listeria, it can grow in refrigerated temperatures if the milk becomes recontaminated.

- Salmonella: If you’ve ever had food poisoning, you probably have Salmonella to thank. While not usually life threatening, Salmonella can cause intestinal issues resulting in vomiting and diarrhea. It is not uncommon to find strains of this bacteria in raw milk, but they are not found in properly pasteurized milk.

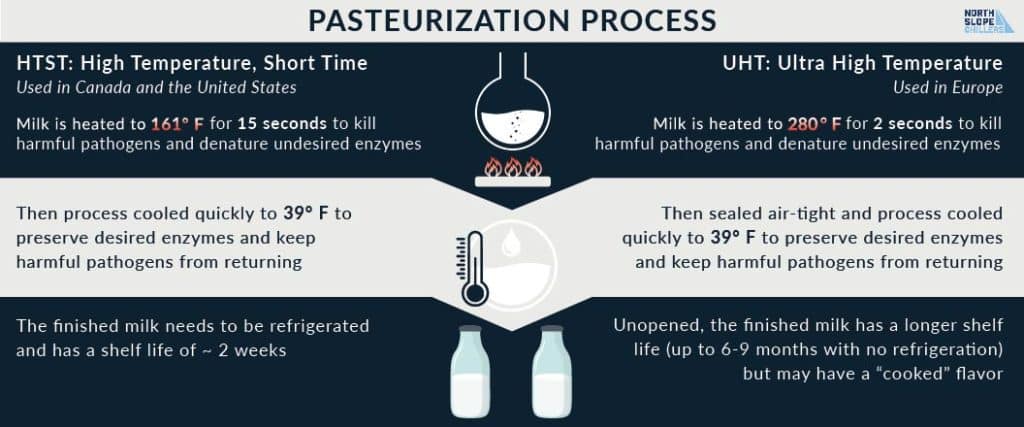

HTST vs UHT

Having killed off these harmful bacteria, pasteurized milk is globally considered safe to consume. However, different countries have different ways of pasteurizing.

Milk in the United States and Canada is pasteurized via High-Temperature, Short-Time (HTST) The milk is heated to a lower temperature (about 165°F) than milk in Europe. The milk is kept at this temperature for about 15 seconds before process cooling kicks in and the temperature is gradually reduced to refrigeration levels. As a result, milk has a shorter shelf life and needs to be refrigerated for maximum storage. Most often, dairy coolers or milk coolers are used to stabilize temperatures.

European dairy producers require much higher temperatures, utilizing a pasteurization process called Ultra-High Temperature (UHT). The temperature of milk is heated much higher than milk processed in the United States, to about 191°F. Unlike HTST, milk is only heated that high for a few seconds. This method allows for milk to be stored without refrigeration and giving it a longer shelf life. The downside is that the milk has a different taste, with some calling it a “cooked” flavor.

Keep it cool

Regardless of pasteurization preference, milk needs to be cooled after being pasteurized so as not to burn the milk into something unfit for consumer tastes. Milk coolers from North Slope Chillers offer temperature control solutions that dairy producers need to lower temperatures after pasteurization and ready milk for market or further processing. Contact North Slope Chillers for the best milk coolers in the dairy industry at (866) 826-2993 or by email at [email protected].