Highway through the “Danger Zone”

Temperature storage zones preserve the flavors, colors, freshness, and health benefits of the food and drinks we all enjoy. The best way to keep food and beverages out of danger is to use industrial food chillers.

The Food Cooling Process

Some foods are either heat-treated or pre-cooked before storage and transportation. For example, dairy is heat treated during the pasteurization process to kill harmful pathogens. These foods must be cooled down quickly to get past the “danger zone” (between 40° F and 140° F). Cooling food down quickly is critical to keep these harmful pathogens from growing. Industrial food chillers help food and beverages pass through the danger zone quickly.

Types of Bacteria Growth

According to the USDA there are 2 main types of bacterial growth in perishable food products: pathogenic bacteria and spoilage bacteria.

Pathogenic Bacteria

Pathogenic bacteria grows rapidly in the “danger zone” between 40°F – 140°F. This type of bacterial growth is hard to detect because it does not generally affect taste, smell, or appearance.

Spoilage Bacteria

Spoilage bacteria grows slowly in the refrigeration zone and gradually affects the smell, appearance, and taste of food. Refrigeration greatly slows this growth but cannot stop it entirely, which is why refrigerated foods still have expiration dates.

Importance of Refrigeration

Storing perishable food below 40° F slows down bacteria growth and extends food’s shelf life. Storing and transporting foods at the correct temperatures does more than just slowing the growth of harmful pathogens. Color, texture, viscosity, and flavors are also preserved when foods are stored at their correct textures.

Different Food Groups Have Different Needs

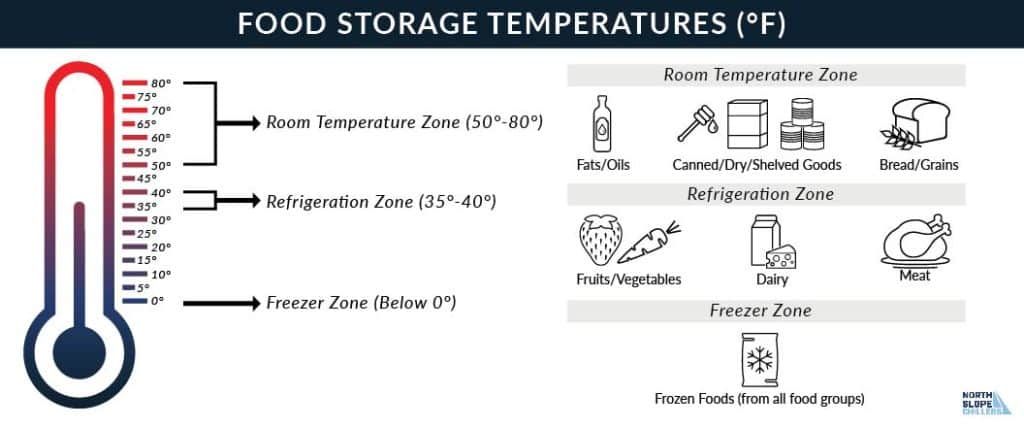

Every food group has different temperature storage and shipping needs. There is no 1 temperature fits all approach to food storage.

About 40% of food products rely upon refrigeration in a well-maintained cold chain through the production, packing, storage, and transportation process. The other 60% need to be stored at either freezer temperatures or at room temperature to preserve their freshness.

Organizing and storing food and beverages according to temperature zones saves energy and keeps the cold where it is most needed. Portable food chillers provide the flexibility and reliability needed to preserve those temperature zones and give you peace of mind.

Contact us to find the right food chilling solution for your needs:

(866) 826-2993 [email protected]