Freeze drying, invented in Paris in 1906, is a very gentle dehydration process used to preserve high quality foods. During WWII, the process was implemented to preserve blood serum. Since then, freeze drying has become a critical process for preserving foods, pharmaceuticals, and a wide range of other products–even cannabis. Cannabis growers are turning to freeze dryers to help them process their crops in response to the rise in the demand of dried cannabis flowers.

Freeze Drying Cannabis: Basic Science and Benefits

Freeze-drying occurs when the solvent (usually water) and/or suspension medium is crystallized at low temperature and removed by sublimation (the direct transition from a solid state to gaseous state without melting). The technical term for this process is Lyophilization.

Three Stages of Freeze Drying Cannabis

There are three stages in the freeze drying process: freezing, sublimation drying, and desorption drying. The freezing phase is the most important part of the freeze-drying process. Rapid freezing is critical and helps eliminate the formation of large ice crystals, which deteriorate the final product quality.

During the drying phase, a high vacuum reduces pressure, and heat provides energy needed for the ice to sublime. This initial drying phase removes about 95% of the water present. This slow step can take anywhere from several hours to two days. Too much heat during this phase could damage final product quality.

In summary, the process runs as follows:

- Deep-freeze: This brings cannabis buds down to – 40°F or below. The colder you can get your product, the fresher.

- Sublimation: This part of the process turns solid ice straight to water vapor, skipping the liquid phase. A vacuum pump then kicks in, sucking out the water vapor.

- Final dry: Now the product is returned to room temp (70-80°F), taking the last bit of water content out of the buds.

Freeze-dried products typically contain between 1% and 4% moisture. These products can be stored between 6 months and 3 years in polybags and 25 years or longer in cans.

Freeze-Drying Cannabis Flowers : How it Started

“When someone walks into a dispensary to look at flower, they want a bud that looks fresh,” says Rich DeLong. “No one wants to buy something that looks shrunken or desiccated.”

Rich DeLong has spent nearly three decades producing freeze-drying equipment that allows florists and other botanical professionals to preserve their products. When approached in 2017 about the prospect of freeze drying cannabis, he started the challenge with a small batch–which failed miserably.

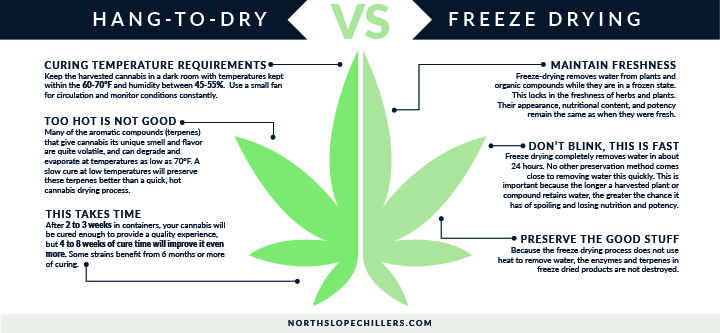

Cannabis flowers are delicate, and the oils, minerals, and terpenes therein are extremely fragile. With this in mind, DeLong created a method for freeze-drying cannabis that maintained an oil and terpene content equivalent to that found in buds that had been left to hang-dry. Hang drying took 18 days, but the freeze-dried plants were preserved and ready for packaging in less than 24 hours.

Freeze-Drying Flowers

Freeze-dried buds start out as fresh flowers. After placing the buds into an extremely cold chamber, sub-zero temperatures quickly freeze the flowers, transforming the water inside to ice crystals. Once those crystals have formed, operators drop the pressure inside the freeze-dryer, to create the vacuum necessary for sublimation drying. That sublimated water vapor is pulled by the vacuum into a colder condensation unit. All that remains is a freeze-dried flower that retains its taste, color, and shape.

“Freeze drying could revolutionize the way marijuana is packed and presented. Imagine a bud looking the same inside a package as it did coming off of the plant,” says Arnovick. “You remove the water, but keep the structure. There’s no mineral loss, no vitamin loss, no terpene loss—just a beautiful flower, ready to smoke,” said Travis Arnovick.

From Farm to Freezer

“A couple years ago, if you told someone you were going to freeze 100% of your crop, they’d tell you you were crazy. Now, we’re seeing 100% frozen harvests, and really large farms: 8,000-pound harvests. It’s totally taken over,” said Ben Grambergu at Grambergu Marketing in Northern California.

Consumers are driving the trend for frozen and freeze-dried plants. Farmers have responded by buying up industrial freezers—plus using dry ice in the fields—and are sending the frozen crops straight to extract labs, skipping the traditional hang-to-dry harvesting process. Freezing preserves terpenes that would otherwise be lost to weeks of drying and curing.

Harvest Right’s Freeze-Dry Process

Freeze-drying cannabis has been around for a while and it’s becoming increasingly popular for small- and large-scale growers. Salt Lake City’s Harvest Right’s Pharmaceutical units shorten the curing process to just 24-36 hours, and are affordable and aimed at both small- and large-scale growers, and even homegrowers. These units preserve buds and terpene profiles better than standard curing because they don’t use heat. Because of the quick cycle of the units and because the curing happens in a controlled environment, there’s a reduced risk of mold or mildew.

Process Cooling and Cannabis

It’s clear that the future of cannabis production directly involves cooling plans and the right equipment to preserve farm-fresh products. For more information about process cooling and cannabis, click here.