Don’t have a cow over keeping your milk cool

Farmers are well accustomed to staying in control over milk temperatures. What methods do they use?

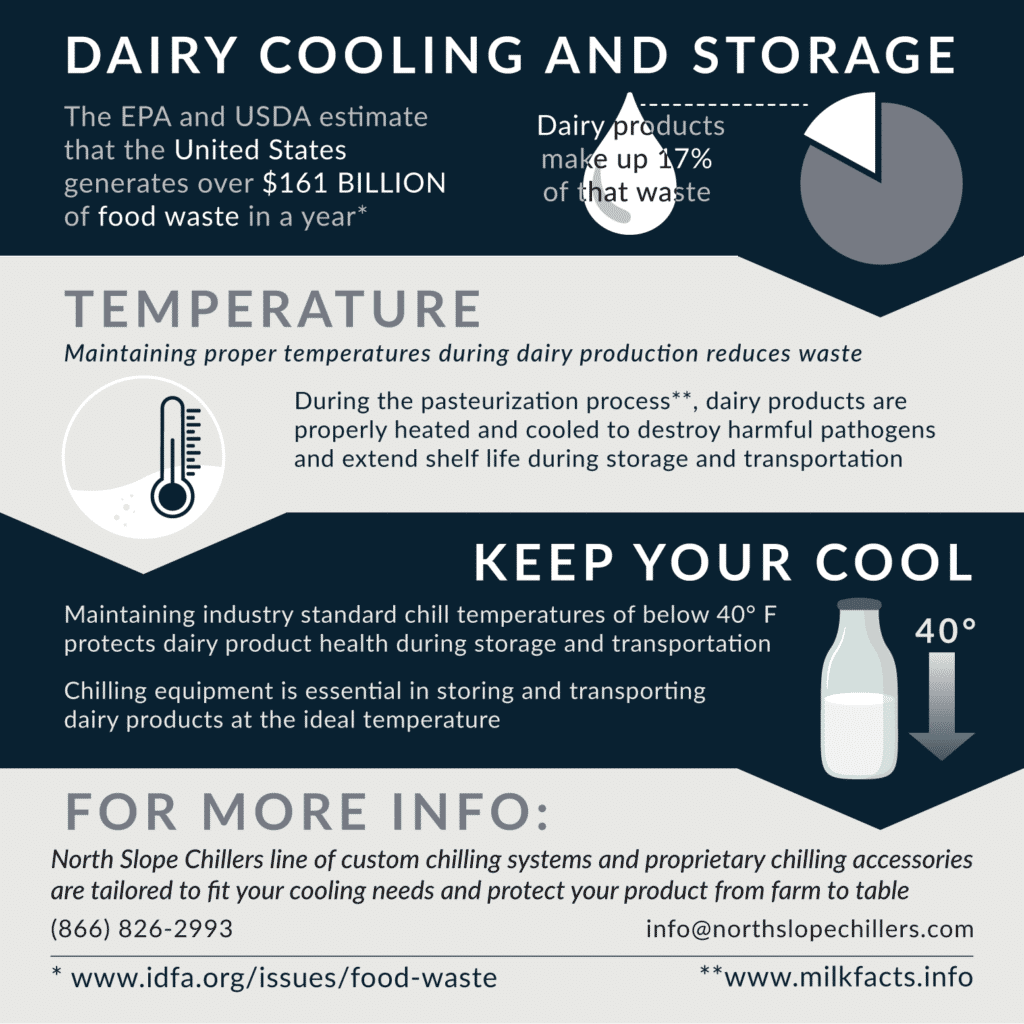

It’s said that you should never cry over spilled milk. When you utilize dairy coolers, you’ll never have to cry about spoiled milk either. In the cooling of milk, stable temperatures are crucial in ensuring it will still be fresh when it reaches the grocery store.

Temperature control for milk starts as soon as it leaves the udder. It leaves the body of the cow at 98° F, but remaining at that temperature would spoil the milk quickly. The ideal range for dairy cooling tanks is between 40° F and 32° F, which balances keeping it above freezing with preventing bacteria growth.

There are two main methods currently used to keep milk cool.

- In-line coolers: Some dairy farms prefer in-line plate coolers because they use less expensive electricity than other milk cooling methods. Milk is precooled by running it through an in-line plate cooler before it is stored in a larger dairy cooling tank. The heat is removed from the milk as water is also circulated in and out of the cooling plate. According to Wisconsin dairy experts, doing so only takes about 10 minutes, as opposed to cooling milk in large batches that can take as long as 45 minutes. Running in-line plate coolers to cool the milk for shorter times can save up to 50% of energy costs, and the water can be reused as long as it was clean going into the plate.

- Process chillers: Often used on large-scale dairy farms, process chillers utilize water or another coolant liquid to remove heat from the milk tank. Chillers pump coolant at low temperatures from the chiller machine to a cooling wrap encasing the milk tank, enveloping it in a blanket of cold. As the heat is absorbed into the wrap, the coolant then flows from the wrap back to the chiller, where it is cooled back down and sent back out to the wrap.

Process chillers are by far the most effective dairy cooling solution. A milk tank wrapped in a Fluxwrap from North Slope Chillers will keep temperatures exactly where you want them, regardless of external climate influences. When connected to Beacon temperature control technology, Fluxwraps and chillers collect temperature data and allow for remote access to milk tank cooling settings.

North Slope Chillers carries everything needed for milk cooling solutions. Contact North Slope Chillers to learn which cooling equipment is right for your dairy needs at 866-826-2993 or [email protected].