What is Cultured Meat?

Lab-grown meat is a new trend in the United States. By feeding nutrients to meat cultures, ground beef and other meats can be grown and harvested without ever needing a cow. However, just as with meat processed from animals, cultured meat requires cooling to help prevent it from spoiling.

Fresh, But Not Farm Fresh

Meat made from animals is a groundbreaking new technology with worldwide implications. Imagine famines no longer happening due to stored cultured meats, or meats ethically sourced from labs instead of sometimes inhumane cattle processing facilities. For these reasons, cultured meat is often referred to as clean meat.

The process for doing so is not that much different that how meat grows normally. Sample cells are taken from an animal and given nutrients to help them grow, developing into muscle tissue. From that point on, further steps are taken as described by Mosa Meat, a cultured meat manufacturer:

When we want the cells to differentiate into muscle cells, we simply stop feeding them growth factors, and they differentiate on their own. The muscle cells naturally merge to form “myotubes” (a primitive muscle fibre that is no longer than 0.3mm long). The myotubes are then placed in a gel that is 99% water, which helps the cells form the shape of muscle fibres. The muscle cells’ innate tendency to contract causes them to start putting on bulk, growing into a small strand of muscle tissue. From one sample from a cow, we can produce 800 million strands of muscle tissue (enough to make 80,000 quarter pounders). When all these strands are layered together, we get what we started with – meat.

The result is referred to as cultured meat. It can be used in the same way as normal meat. Hamburgers, hot dogs, etc. According to a June 2019 Forbes article, the process from retrieving cell samples to eating lab-grown stroganoff takes only two to six weeks.

Economy of Scale

Companies like Mosa Meat have already created meat processed from cow cells, producing hamburgers and other foods. The first burger to be made with cultured beef by Mosa Meat cost more than $227,000 due to the small amount of meat being grown at the time. Scaling up production ideally would bring the cost down. Doing this would require utilizing bioreactors, large cooking vats used in creating cheese.

Keeping it Cool

As will all meat products, temperature control is vital to maintaining freshness and in preventing bacterial growth that would cause meat to spoil. However, the scale of cultured meat production can have negative effects on the ability to keep provide adequate refrigeration. The larger the system is used in culturing meat, the less efficient the cooling processes typically are.

Chillers in Cultured Meat Production

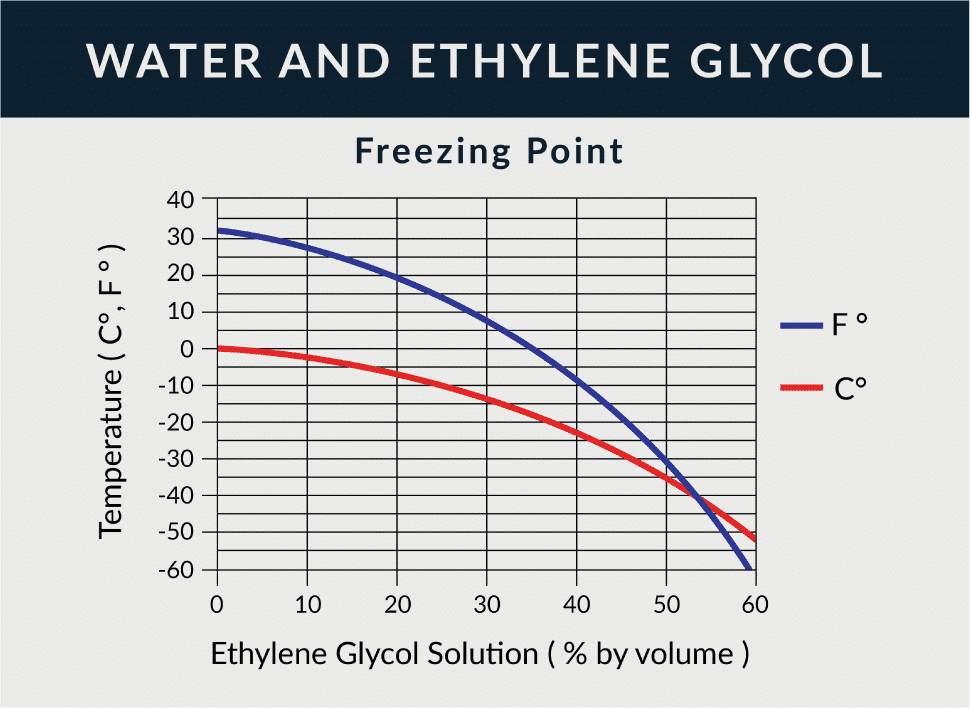

Chillers stand out in cooling needs for their ability to provide consistent, even temperatures to even the biggest of industrial applications. They are capable of using fluids to lower contact temperature well below zero, which is more than what is required for cultured meat production.

North Slope Chillers

For the most efficient and reliable chillers on the market, use North Slope Chillers for all of your cultured meat needs. Whether you’re experimenting with beef growth in the lab or producing massive amounts of clean meat, North Slope Chillers manufactures the chilling equipment needed to keep you in control of temperatures from start to finish. For more information about sizing or custom chilling options, call our chilling engineers at (866) 826-2993 or reach them by email at [email protected].