What Goes Around Comes Around

Centrifugal chillers are one of the hardest working machines behind the comfort that we enjoy everyday. When we visit movie theaters, grocery stores, or office buildings and feel the cool relief of air conditioning as we enter, we have centrifugal chillers to thank.

Centrifugal chillers are typically the most economical chiller to use for cooling sizable buildings. They can efficiently produce a high flow rate and are ideal for larger applications. Centrifugal chillers usually have fewer moving parts than other varieties, and with less mechanical friction are more cost effective to maintain. Some cooling applications require greater portability and lower cooling temperatures than centrifugal compressors are built to produce. Their range of usefulness is limited by their large footprint and emphasis on volume instead of cooling power.

Types of Compressors

Positive Displacement Compressors

There are 4 main types of compressors found in vapor compression chillers: scroll, screw, reciprocating, and centrifugal. Scroll, screw, and reciprocating compressors work through the process of positive displacement. Positive displacement compressors capture gases into a chamber, then reduce the volume of the chamber to cause compression.

Centrifugal (Kinetic) Compressors

These compressors use centrifugal force to turn kinetic energy into pressure. As gases enters the compressor, they are spun radially outward causing them to compress. Centrifugal force then throws the gases back out at a high velocity.

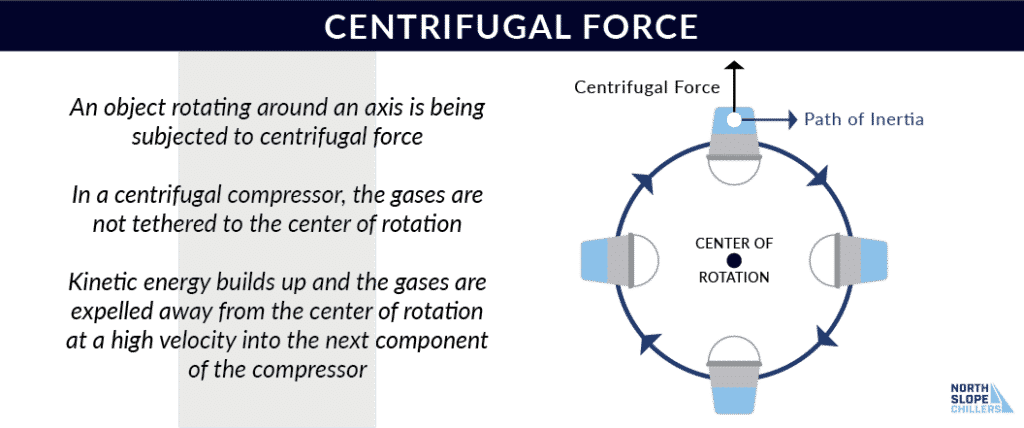

Centrifugal Force

Centrifugal force is an inertial force that acts on all objects rotating around an axis. It is the same compressing force you feel in many carnival rides or when you make a u-turn in your car, and is a very energy efficient method of compression.

A common centrifugal force experiment is to take a bucket of water and, with a straight arm, quickly rotate at the shoulder and swing the bucket upward and around a vertical loop. Centrifugal force compresses the water enough to counteract gravity so that even when the bucket it upside-down, the water stays in the bucket.

Centrifugal compressors take this force one step further with expelling the gases out at a specific point in the radial spin. This is best explained by imagining a ball at the end of a rope. If you were to swing the rope vertically around an axis (your hand) at a high velocity, centrifugal force will be pulling the ball outward. When that rope is released at the correct angle, the ball will exit the loop at a high speed and be hurled upward.

Parts of a Centrifugal Compressor

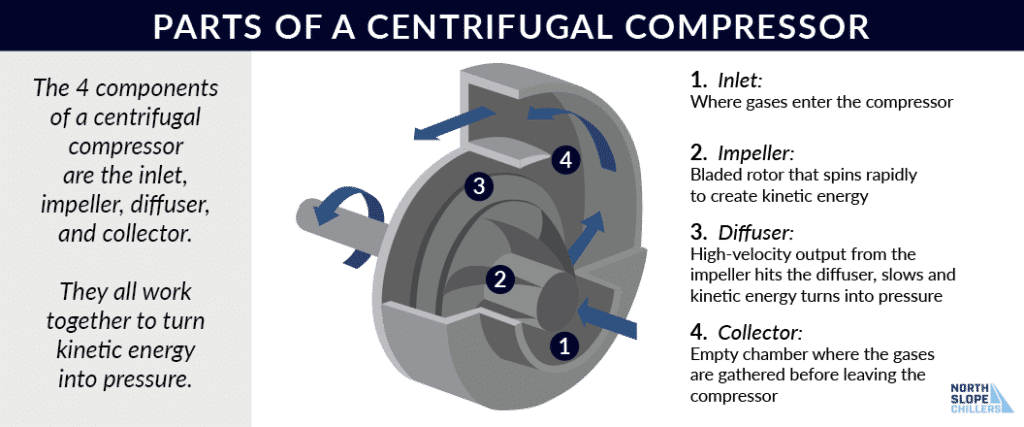

Basic centrifugal compressors are made from 4 main components: an inlet, impeller, diffuser, and collector.

Inlet

An inlet is a pipe in which the gases enter the compressor. Some inlets are open and simple, others contain valves or channels to direct flow in the direction needed inside the compressor.

Impeller

Impellers are the key component in generating centrifugal force. Rotors with carefully angled vanes or blades spin and raise the energy of the gases inside the compressor.

Diffuser

These high velocity fluids or gases are thrown outward and hit the diffuser which converts the kinetic energy into pressure by reducing the velocity. Diffusers accomplish this in a variety of ways, such as channels or wedged vanes for the high velocity substance to compress against.

Collector

The collector is an empty chamber which gathers the flow coming out of the diffuser. The shape of a collector varies greatly but typically resembles a nautilus shell so it can collect around the entire radius of the impeller and diffuser. Collectors can also sometimes contain valves or other components.

Chilling Solutions

Industrial chillers and their components should be carefully selected so they are ideally situated for the application at hand. Understanding the function and benefits for different compressors can help you find a tailor made chilling solution for your needs.

Chilling Solutions From North Slope Chillers

North Slope Chillers offers easy to install, portable chillers that won’t disrupt your current setup. Contact us to find the chilling solution for your needs:

(866) 826-2993 [email protected]