Son of a…what?

Home brewing has become a very popular practice in recent years. Quick digital access to brewing methodology, online ordering of high quality grains/hops/yeasts, and a growing nationwide appreciation for craft brewing have all fed into a renaissance movement of brewing as an artistic science. With all these ingredients and instructions at our fingertips, finding the right method for you can be a process of trial and error. Let’s examine one of these DIY methods in greater detail…the “son of a fermentation chiller.”

Fermentation Stage

So you have carefully selected your grains, mashed them, malted them, turned them into wort, and cooled your liquid wort so it is ready to be pitched to your yeast. The most crucial part of the brewing process is about to begin…fermentation. The fermentation stage is a tricky one, in that it can ruin all your hard work leading up to this point if your brew’s environment is not carefully protected.

The most important environmental factor in fermentation is temperature. Under the right conditions, yeast will wake up, consume the sugars in your wort, and turn them into alcohol and carbon dioxide. Under the wrong conditions yeast that is too cold will go dormant and not finish fermenting; yeast that is too hot will produce off flavors and aromas or even die off completely.

Enter Fermentation Chambers

Fermentation chambers are specially designed containers to protect the environmental conditions while your brew ferments. They not only protect your brew’s temperature, but reduce exposure to excess oxygen and unwanted pathogens.

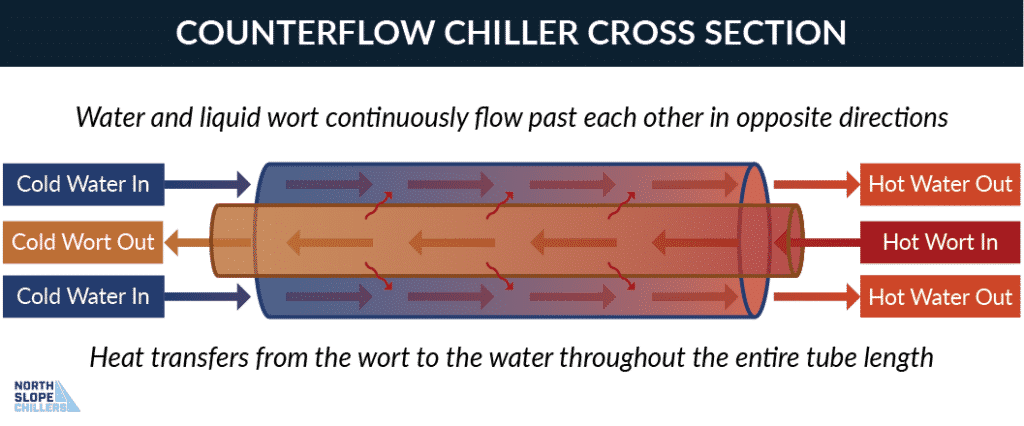

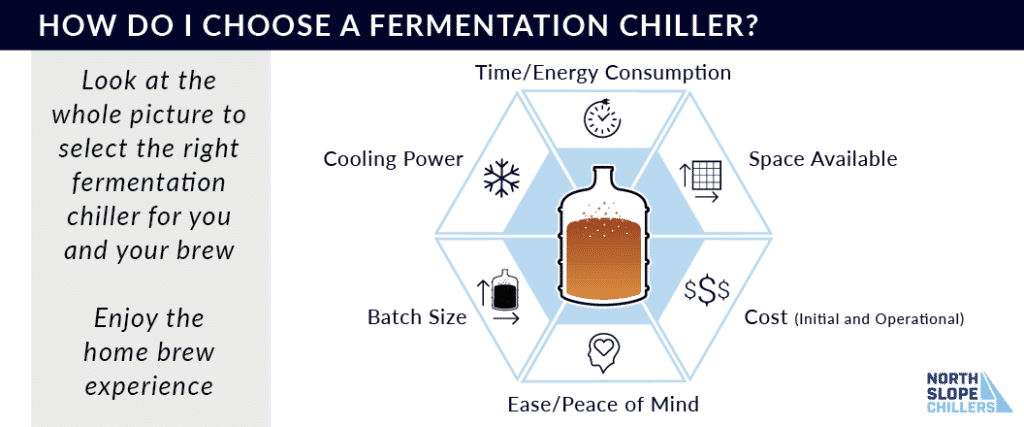

There are many different fermentation chambers used by home brewers. They vary widely depending upon batch size, cost, how much brewing space you have, and how much of your time and energy they consume. Since fermentation is an exothermic process, your brew will continuously generate heat as it ferments. So how do you keep your fermentation temperatures in the ideal zone without babysitting your brew around the clock? The solution is a fermentation chiller.

Son of a Fermentation Chiller

Home brewers use many methods to chill their fermentation chambers and one of the more popular DIY methods is to construct a “son of a fermentation chiller.”

First designed by home brewer Ken Schwartz in 1995, the whimsically named son of a fermentation chiller has become a common creation among American home brewers. The plans have been redesigned through the help of feedback from other home brewers, but the basic concept is the same.

This fermentation chiller involves building a chamber made of thick insulation foam boards. The brew is housed inside next to rotating jugs of ice, a fan, and thermometer.

Weighing Pros and Cons

Cost

One of the most appealing aspects of the son of a fermentation chiller is the cost. Low cost materials can be easily purchased and if you possess basic construction skills, it can be easily assembled.

There may be additional costs in the future such as purchase of a second thermometer to make sure you are not just measuring the air temperature inside, but the temperature of your brew itself.

However, cost is only 1 of the factors to consider when looking at your home brew fermentation options.

Batch Size

The larger your brew batch, the more heat will be generated by the fermentation process. The son of a fermentation chiller can be adapted to accommodate up to 7 gallons, but for larger batches, fans and ice will not be sufficient to protect your brew from thermal stress.

Cooling Power

The appeal of buying a small fan to save upfront costs can cause problems in the future. Make sure you have enough cooling power to handle a large, constantly self-heating container of wort.

Time and Energy Consumption

Before home brewing, you need to carefully look at how much time and energy you have available to switch out frozen jugs as they melt and need to be replaced.

Using the son of a fermentation chiller also means spending time carefully monitoring your thermometer.

Space Available

When using a son of a fermentation chiller, the footprint of the chiller may be small, but you will need ample freezer space to store your rotating frozen jugs.

Ease and Peace of Mind

Picture how you would like your home brewing experience to pan out. Balancing work and effort with the enjoyment of sharing your batch with your family and friends is an important aspect of home brewing. Investing in a home brew system can provide long term enjoyment if you carefully weigh your chilling options before hand.

North Slope Chillers Solutions

Be sure to look at the whole picture when embarking upon your home brewing journey. Low cost options seem convenient at first, but can lead to frustrations in the future. Using a reliable fermentation chamber chilling jacket, and fermentation chillers can save you time, energy, and provide more consistent brewing results. North Slope Chillers Fluxwrap jackets and fermentation chillers can transform you from home brew babysitter, to home brew master.

Contact us to find the right fermentation chilling solution for your needs:

(866) 826-2993 [email protected]