What is BTU?

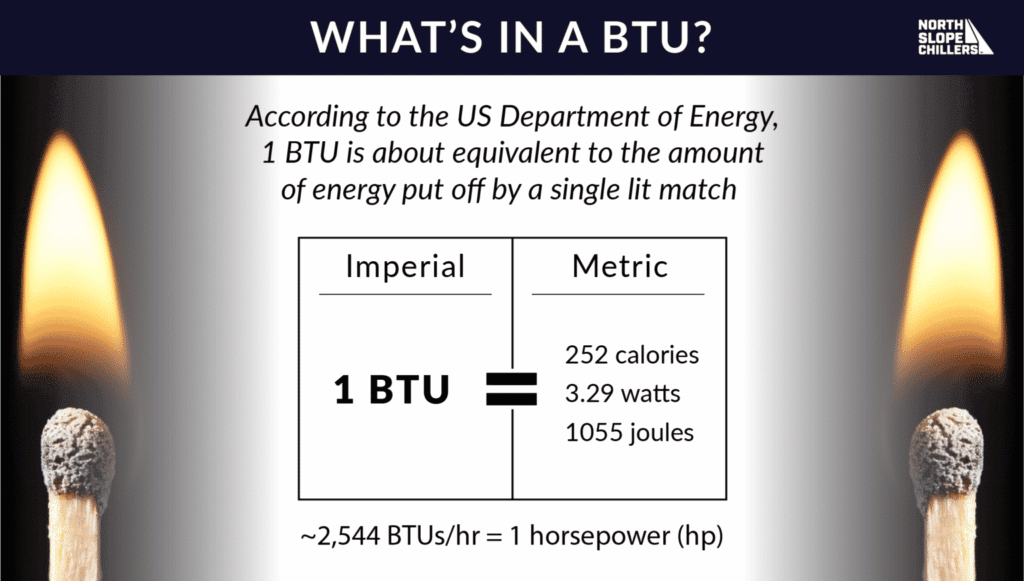

BTU is short for British Thermal Unit. It is defined as how much heat it takes to raise one pound of liquid water by one degree Farehnheit.

How much is a BTU?

A single BTU is very small. So small, in fact, that you could only notice the heat if you were directly near its source.

The United States Department of Energy states the following:

A single Btu is very small in terms of the amount of energy a single household or an entire country uses. In 2020, the United States used about 92.94 quadrillion Btu of energy. Written out, 1 quadrillion is a 1 followed by 15 zeros: 1,000,000,000,000,000.

BTUs are usually pretty high in number when using them as a measurement for industrial purposes. You usually won’t find readings for heat measurement when you’re only dealing with a few BTUs. That’s because (for the most part) heat within a system begins to matter when it starts to influence the entire interior space of a building. For example, the average home size in the United States is a little more than 2,000 square feet. A home that size in a standard climate (not too hot in the summer, not too cold in the winter) will measure about 90,000 BTU.

Where does BTU come from?

There isn’t much that is British about the British Thermal Unit. Oddly enough, the United States is one of the few countries that regularly uses BTU to measure heat. Other nations, including the United Kingdom (Great Britain), refer to heat as a unit of energy. For this, they measure heat using joules and calories. One BTU is equal to about 1055 joules, which also equals roughly 252 calories.

The beginning of BTU

BTU came into the world as the steam engine began to make its mark on the world. With the Industrial Revolution getting underway in the British Empire during the 1700s, steam power was seen as an efficient new way to provide energy for new factories and heavy equipment.

As wonderful as steam engines were to the emerging manufacturing scene, it was clear that these powerful machines needed to be cautiously calibrated and maintained extremely well. Unregulated heat often resulted in everything from loss of steam to boiler explosions, leading to lost production and injuries. Sometimes, in tragic boiler explosions, workers and others were killed.

Here’s more about the history of BTU from our past blog article, “All About BTUs”:

After the 17th Century, as steam powered technology became more common, scientists needed a more precise method of measuring heat. Steam engines require careful calibration and calculation to make sure pressure limits stay within safe boundaries. As a result, British scientists began refining the metrics they used to measure heat energy. The exact origin of the British Thermal Unit (BTU), and who coined it, is unclear. However, engineering publications began referencing BTUs in the late 19th century. It became a standard thermal energy unit for the imperial measurement system.

Meanwhile in 19th Century France, Nicolas Clement was formulating a unit of heat measurement that became known as the calorie. Calories are now the standard thermal energy unit for the metric measurement system.

Is BTU used in the metric system?

BTUs are a part of the Imperial system of measurement, including feet, inches, pounds, gallons and miles. While not used in the metric system (the metric system utilizes calories and joules), they play a critical role in determining the price of natural gas in the United States. It seems like BTU will remain a staple as a unit of measurement due its impact on the nation’s economy.

How to measure BTU output

As stated at the beginning of this blog post, one BTU is the amount of heat it takes to raise one gallon of water by one degree Fahrenheit. The same formula works for heating air, but with a few minor changes.

How to measure BTU for a room

When doing the math to figure out how much heat it takes to raise the temperature of a room, remember this: one BTU is enough to raise the temperature of about 30 ft3 of air by one degree Fahrenheit.

There are three steps for finding the BTU for a room:

- Measure the length, width, and ceiling heighth of the room

- Account for the EPA’s recommended BTUs per square foot formula

- Add environmental factors that could impact heating and cooling resources in the room.

Measure

First, measure the length of the room you intend to find BTUs for. Also measure the width and the height of the room up to the ceiling. Multiply the length and the width to find the square footage. We’ll need the colume of the room separately later on, and to get that you’ll multiply the square footage by the ceiling height. This gets tricky for any room that isn’t rectangular or square, but do the math and you can move on to the next step.

The best way to understand anything is to practice it, so let’s say the room we’re trying to heat is 1,000 square feet with a 10-foot ceiling height. That’s a total volume of 10,000 ft3.

EPA Formula

Once you have figured out the dimensions of the room, plug those numbers into the U.S.’s Environmental Protection Agency’s recommendations for how many BTUs are needed for any given building interior. The EPA says that for every one square foot of space, you will need at least 20 BTUs.

In our example, we have a room that has an interior of 1,000 ft2 that needs to be warmed or cooled. 1,000 times 20 is 20,000. This means that it takes 20,000 BTU to be sufficient to warm or cool a room that is 1,000 ft2.

Factors That Can Affect the Amount of BTUs Needed

Though we’ve now calculated the exact BTU for the room, we’re not quite done. Unless the room you plan on measuring BTUs for is a concrete box with no way in or out, you will need to consider anything that could have an impact on room temperature. For example, a window could impact how cold or how hot the room gets if the other side of the window is outdoors.

Other examples include:

- Location: is the room within the interior of the building? Are any of the walls of the room used as the edge of the building?

- Insulation: how well is the room insulated? A building made solely out of cinderblocks will retain heat poorly compared to a wooden building with fiberglass insulation.

- Body heat: how many people will be in the room? Humans generate a lot of heat, and have the ability to significantly heat up a room themselves.

- Open doorways: people moving in and out of the room will disrupt any temperature consistency.

- Vents and windows: warm air can leak out of a room through many ways. Windows and vents are primary culprits in heat loss. Glass windows, as well as the window frames themselves, will conduct heat away from the room. Vents allow for airflow to move in and out of the room, making consistent air temperature an even greater variable.

- Humidity: The amount of BTUs needed for your process cooling system will also be affected by the ambient temperature and humidity. If the ambient temperature is high, you will need more BTUs to achieve the desired cooling effect. If the humidity is high, you will need more BTUs to remove the moisture from the air.

Additional tips for figuring out BTU

- Remember, a low BTU count isn’t just a lack of heat: it’s how you go from a higher temperature to a lower temperature. The amount of BTUs needed for a room to cool down will always be less than how many BTUs it takes to warm the room up.

- Heat is heat, no matter what is used to create it. From electrical coils to burning wood, all heat is measured in BTU.

- Learning how many BTUs are needed to heat up a room is just as important as how many BTUs are needed to cool down the room.

How to select the right size process cooling unit

Choosing the right process cooling unit depends on what you’re using it for. If you’re trying to manage the temperature in a room, you’ll want to select a larger unit that feeds cooled air directly into the environment. If you plan on using your chiller unit to lower temperatures on specific materials, a smaller unit would make more sense.

At North Slope Chillers, we have every size of chiller available organized into three categories: Frost, Freeze, and Deep Freeze. Our engineers can help you calculate the BTUs needed to manage temperatures for your chilling needs. We offer custom chilling solutions that can fit every chilling need you have.

Email us at [email protected] or give us a call at (866) 826-2993 to get started on your path to chilling peace of mind.