Go With Against The Flow

The brewing process is a roller coaster of temperatures…warm, hot, boiling/roasting, rapid cooling, maintaining warmth, stable aging and storing. Hitting the right temperatures at the right times ensures the chemical reactions finish their work and produce a high quality brew with all the desired flavors, aromas, alcohol levels, and colors intact. Let’s look at the most drastic temperature change in the brewing process…wort cooling.

Wort Creation

Brews begin their lives as starchy grains that are sprouted, cracked, and then steeped in hot water. After this hot mash converts starches into sugars, the solids and liquids are separated (through lautering) and the result is…liquid wort. Before these sugars can be pitched (fed) to yeast, they need to be sanitized. Wort must be heated to its boiling point (212° F) to kill any harmful pathogens that can compromise the fermenting process that follows.

Wort Cooling

Before pitching wort to your selected yeast strains, it must be cooled, and quickly.

What’s the Rush?

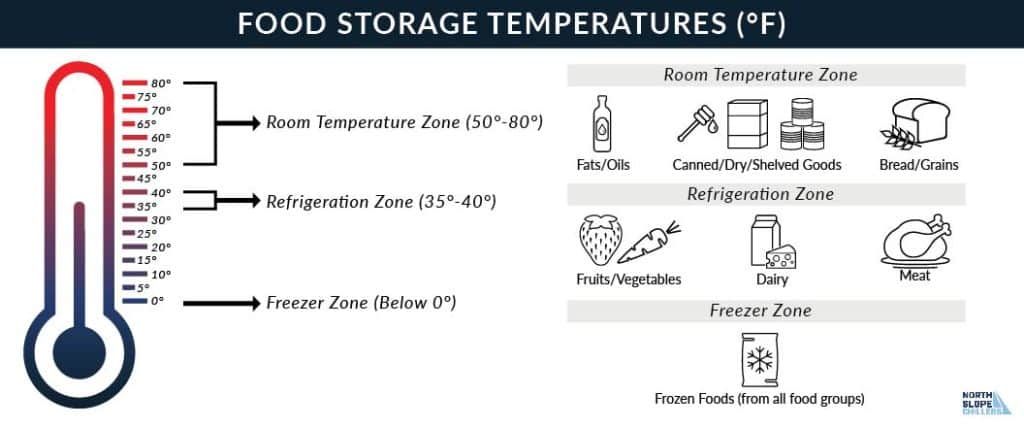

Just like dairy pasteurization, rapid cooling ensures the wort passes through the luke warm zone (80°-140°F) as fast as possible. Unwanted microorganisms, like bacteria or wild yeasts, love the luke warm zone and can infiltrate your brew if it lingers in this temperature zone for too long. A lengthy stay in this zone can also increase the production of dimethyl sulfide (DMS) which will make your brew taste unpleasantly like canned corn.

Prepare to Pitch

Quickly cooling your liquid wort also prepares it to be pitched to your yeast. Yeast only ferments at very specific temperatures, and each strain prefers a different temperature range. If the liquid wort is too hot it, will instantly kill the yeast upon contact and your brew will never ferment. Careful research will let you know what temperatures your chosen yeast cultures prefer so you can prepare your wort accordingly.

There are multiple wort cooling methods, and some are more efficient than others

Counterflow Chilling

The most effective method of wort chilling is counterflow chilling.

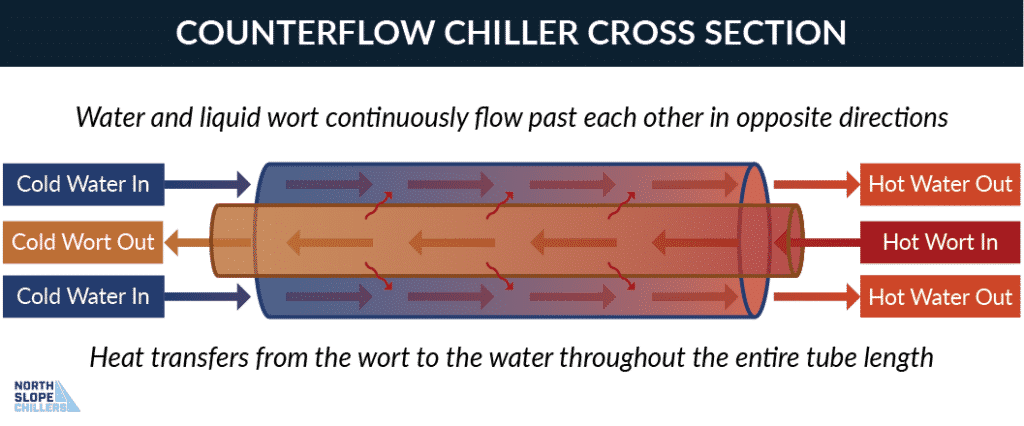

A counterflow wort chiller is a coiled section of double layered tubing. Hot liquid wort is gravity fed through the inner tube in one direction, and cold liquid is pumped through the outer tube in the opposite direction. This counterflow in opposite directions greatly speeds up the heat transfer process and cools the wort quicker.

Other cooling methods, such as immersion chilling, rely on cool baths to chill the wort. But still water baths are much less effective than flowing water. Counterflow chilling keeps the cooling liquid and wort continuously flowing in separate tubes so they never come in contact with each other; the only thing that passes between the two liquids is heat.

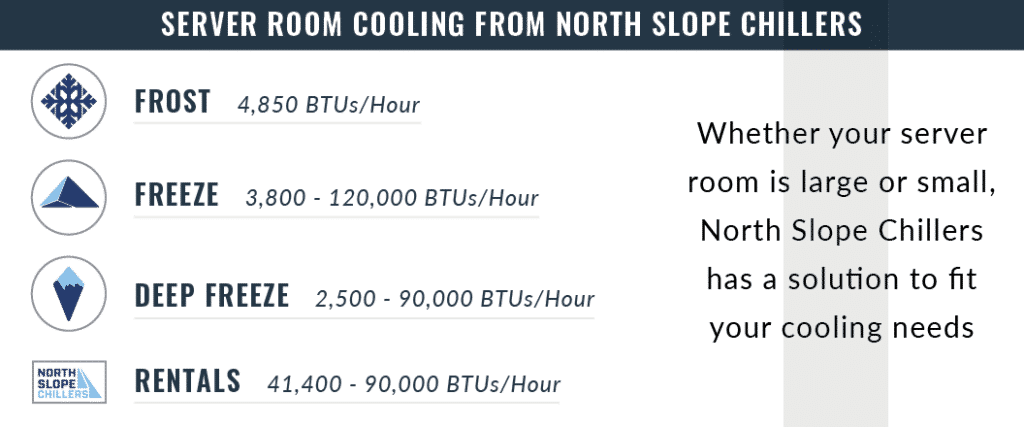

Wort Chilling With North Slope Chillers

The perfect accessory for your counterflow system is an industrial chiller that can cool your wort down as quickly as possible. North Slope Chillers’ lines of industrial chillers contain powerful pumps to provide cold water on demand to maximize your counterflow’s effectiveness.

Contact us to find the right wort chilling solution for your needs:

(866) 826-2993 [email protected]