Glycol: A Critical Chemical

Glycol is a common liquid used in process cooling across many industries. But is it the right one for your chilling needs?

Process Cooling

Process cooling systems are a critical part of most manufacturing industries. Heat energy is built up as materials are put together and chemicals are combined. Process cooling allows those materials to be held at a stable temperature while the manufacturing process around them continues without heat becoming a worry.

The use of process cooling is widespread. These are only a few examples of the ways process cooling systems are used across the globe:

- The plastic industry needs cooling to reduce the time it takes to create products using injection molding.

- Cooling is used in the creation of pharmaceuticals when removing heat from medicinal vats as products move from the manufacturing stage to the containment and packaging stages.

- Newspaper, books and magazine printers require process cooling to lower ink temperatures and in removing heat from friction caused by print rollers.

- Home brewers, craft breweries and microbreweries use process cooling to make sure their brews are kept at the right temperatures while fermenting.

Different cooling liquids

Not all process cooling systems are created equal. There are a number of different types of heat-removal liquids that are used to effectively control temperature. These include water, deionized water, dielectric fluids and glycol. Let’s go over the pros and cons of using each cooling liquid:

Water

The most common liquid used in cooling, water is cheap and easily obtainable. An additional benefit is that water is a stable, nontoxic liquid, making cleanup easy in the event of spills. On the downside, water is extremely corrosive thanks to impurities in it such as chlorine, a common additive to tap water. Calcium buildup is also likely due to the fact that it too is generally found in tap water. Using filters, corrosion inhibitors or pure water can help remove these impurities.

Deionized Water

Basically water without additives, deionized water has all of the ions removed from normal water via filter, reverse osmosis membrane and deionization system. The only real advantages deionized water has over other cooling liquids is that it’s safest to use for electrical manufacturing, due in part to the water having high resistance properties. However, this same feature also causes the water to be acidic upon exposure to the open air, leading to non-stainless steel pipes corroding.

Dielectric Fluids

These fluids, such as castor oil, liquid oxygen or mineral oil, are also mainly used in electronics to keep equipment cool while providing electrical insulation. Dielectric fluids are often tailored to the material they serve and are very expensive as a result.

Glycol

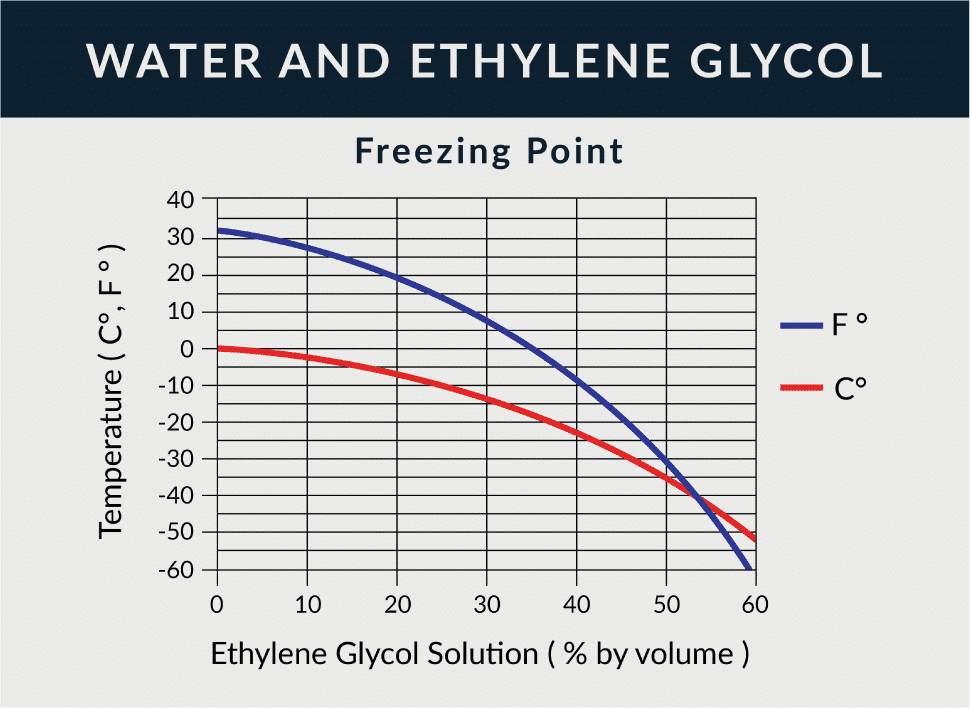

A toxic liquid, ethylene glycol is mainly used as an antifreeze and for corrosion prevention. In addition, glycol has a low viscosity, negating the need for high-powered pumps that other cooling liquids might require. Glycol is the chemical of choice in process cooling due to its ability to reach extremely low temperatures without thickening or freezing. When combined with water, the freezing point of the collective chemicals reaches well below zero.

For most companies, a glycol chiller is the cooling system of choice to keep the heat away. Chillers pump cold liquids, usually water, glycol or a mixture of both, through heat-creating machinery via pipes or wraps. The cooling liquid absorbs the heat and brings it back to the chiller, which removes the heat and sends the liquid back out at a low temperature in order to draw away more heat.

Other chemicals can be used in process cooling. However, these chemicals don’t have the same temperature reach that glycol does, are less effective for general use, or are too expensive for most businesses.

Glycol in Chillers

North Slope Chillers recognizes the unique requirements that individual businesses have in process cooling, especially when using glycol. Glycol heaters and chillers are tantamount to achieving the best result. That’s why each chiller system is created to be the solution to specific temperature control problems. Chillers can be custom ordered according to size, flow rate, fluid variations and more.

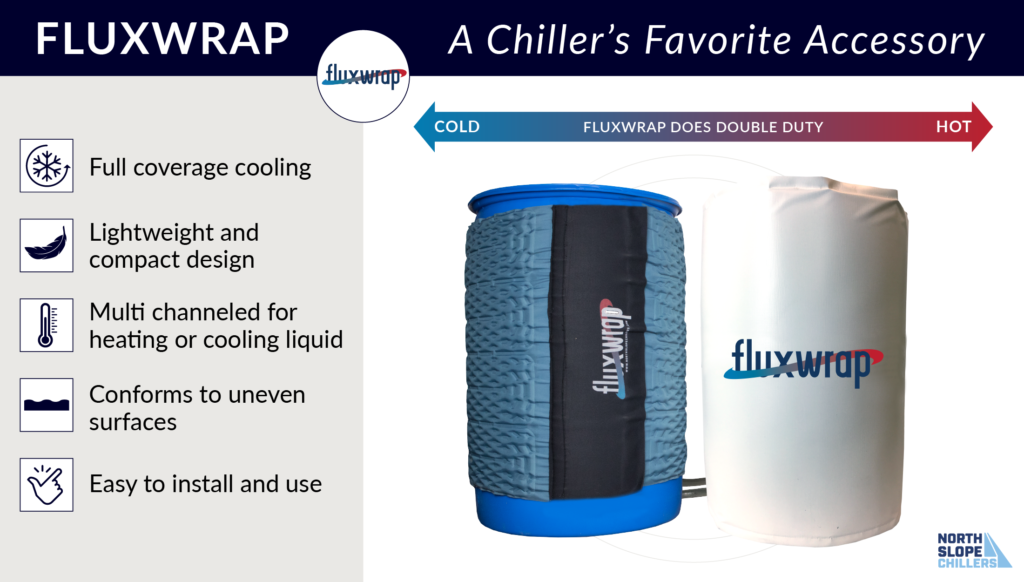

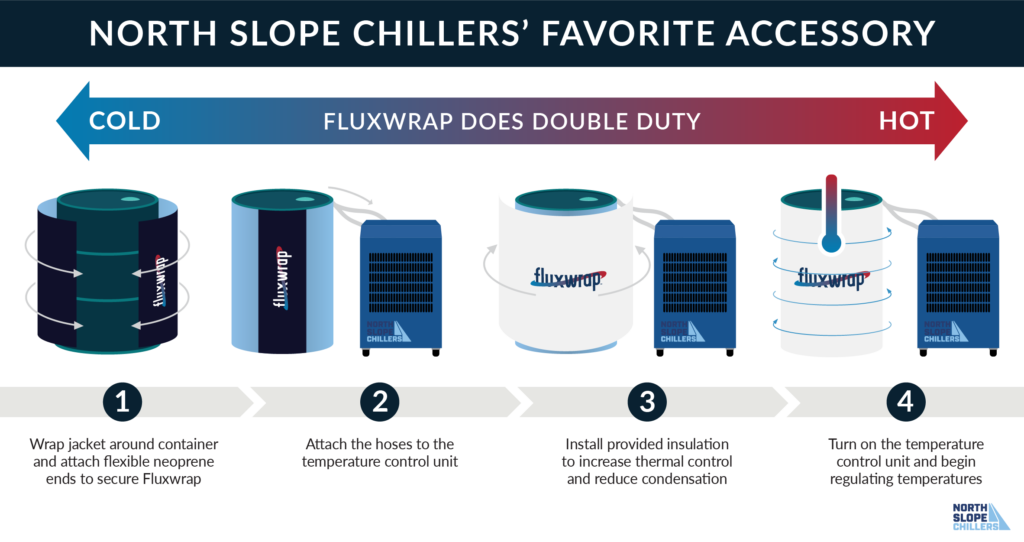

Other issues that might arise in process cooling might be more along the lines of storage cooling, an issue that Fluxwrap was born to take care of. Fluxwrap is a cooling wrap that works with a chiller system to encase a container or drum in a blanket of cold, keeping your material at a stable temperature.

Learn More

North Slope Chillers is here to meet your process cooling needs. Even if your cooling problem is uniquely specific, our team of custom chiller builders are here to find a solution and get you back in control of your temperatures.