Visit any large city in the United States today, and you’ll discover an ever-increasing amount of craft and microbreweries. Microbreweries and craft breweries are similar in almost every way, with a few exceptions.

The American Brewers Association says microbreweries are allowed to make only 15,000 barrels of beer (460,000 gallons) per year and must sell 75 percent of its inventory outside of its brewery location. Craft breweries can’t produce more than 2 million gallons of beer per year. In addition, craft beers must be made with 50 percent malt and are independently owned.

It’s easy to mix the two up. One thing they do have in common is that many craft and microbreweries begin with people creating new beer concoctions in their own homes, known as homebrewing.

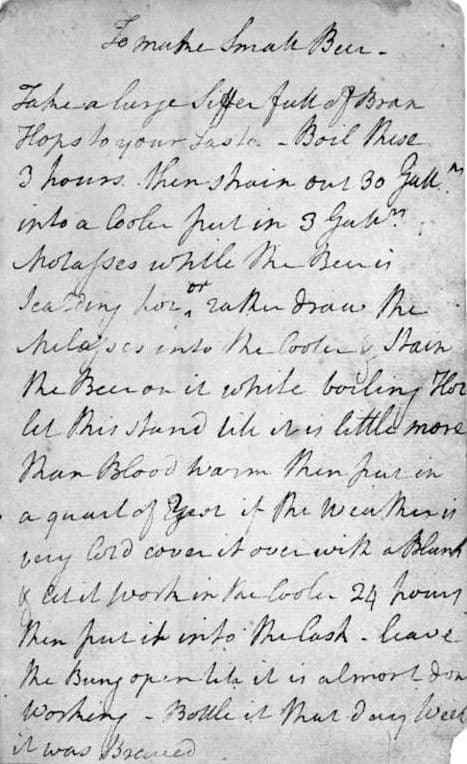

Homemade beer was, at one point, more American than baseball. When they were not establishing new countries and fighting oppressive powers, George Washington, Thomas Jefferson and James Madison were home brewers.

At that time, beer was consumed more than water. According to the American Homebrewers Association, “Beer has long been a beverage brewed as a source of potable water in areas with disease- and famine-stricken resources, as was the case in some instances in America.”

Revolutionary War-era brews were not flavorful, nor did they provide a “buzz”. These early American beers were often referred to as “soft” or “weak” due to their low alcohol content, but were popular enough that they led to the creation of craft and microbreweries, which populated many American cities until Prohibition began in 1920.

They virtually disappeared until the 1980s, when craft and microbreweries began making a comeback. During that decade, a new community of craft brewers started expanding out of their garage homebrewing hobby into commercial opportunities, giving Americans back the tradition of flavored ales and lagers. It was a revolution in its own right.

Since then, craft brewing has exploded into its own industry in the United States, with California, Colorado, Washington and Oregon boasting the most craft breweries. Compared to just eight craft brewers in 1980, there were more than 6,000 in 2018. Frankenmuth Brewery, a craft brewery based in Michigan and the oldest operating craft brewery in America, claims most Americans live no farther than 10 miles from a craft brewery. The culture of small, independent breweries has become something that drinkers can connect to, and participate in.

Craft and microbrews today are rich in flavor and are considered an art. These artisan brews contrast greatly with what some beer critics call “buzz beers,” such as Budweiser or Miller Light, which people drink more for the buzz they get instead of deep flavor. Whether you prefer sour ales or a rich lager or a stout IPA, there’s something for all beer drinkers so long as craft and microbreweries continue to thrive.