What is EDM?

EDM (electrical discharge machining), also known as spark machining, is a manufacturing process used to obtain a specific desired shape in metal by applying electrical discharges(sparks). There are a few different types of EDM technology including sinker EDM, wire EDM, ram EDM and fast hole drilling EDM; all of which are primarily used for hard metals that would be very difficult to machine with alternative methods. Even though electrical discharge machining is ideal for hard-to-drill materials, it can also be used for softer metals.

Photo: Advanced Machinery

Key components:

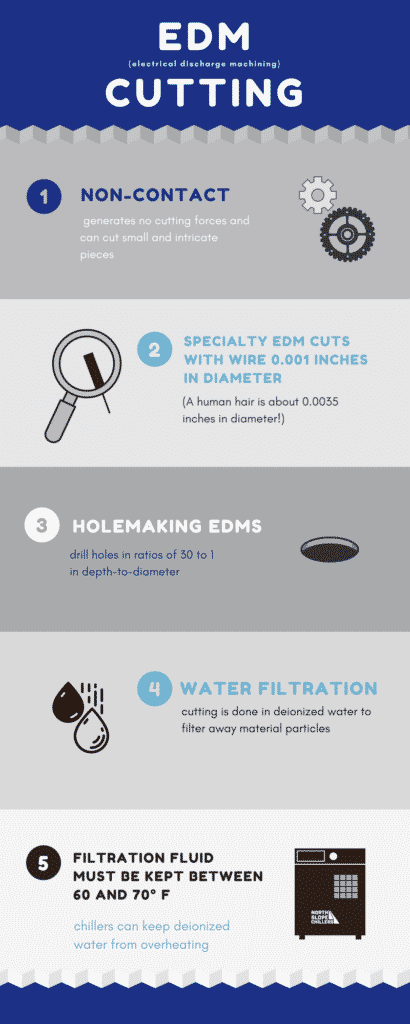

A typical EDM system consists of a CNC unit, a power supply with anti-electrolysis circuitry, automatic wire threading, a tank of dielectric fluid(deionized water), a filtration system and a spindle chiller to keep the fluid at a steady temperature. In order to control the spacing of the sparking gap between the electrodes and workpiece, the piece of metal that’s being cut is completely submerged under dielectric fluid or deionized water.

Photo: Makino Resources

Water filtration and temperature

When it comes to using electrical discharge machining, the water serves as a key component. To get the best performance from an EDM machine, the water must be kept as clean as possible. During the EDM process, some of the metal goes into the water as small particles. The water is filtered and deionized(demineralized) in order to remove those metal atoms. Process cooling deionized water helps to promote a higher metal removal rate and enhances the machine’s capacity to deliver a more precise cut.

In addition to cleanliness of the water, the water temperature is important as well. In order to ensure that the deionized fluid maintains a consistent temperature of 60-70 degrees Fahrenheit, a water chiller is essential during the EDM process. The machine will fail to cut precisely, slow down processing, and not last as long if these standards are not met.

Industries using EDM:

EDM is used everyday in various ways in a lot of familiar manufactory such as 3D printing, medical instruments, moulds, gears, jewelry, telecommunications, guns and many more.

3D Printing: Project Daniel

With the ability to create molds of any shape or size, 3D printing seems to be almost limitless. Similar to 3D printing, there are practically zero mechanical forces when using EDM because the sparks do the cutting. Since not all 3D printers can cut metal, EDM is used to shape the necessary metal pieces. From using 3D printing to produce 3D ultrasounds–yes, it’s a thing– to providing prosthetic limbs for children, the innovative style 3D printing has obtained with the help of EDM is astonishing.

16 year old, Daniel Omar, is an inspiring example of the amazing things we are capable of accomplishing with the technology of 3D printing and EDM. After a traumatic accident in South Sudan, Daniel lost his arms at age 14. Thanks to Dr.Tom Catera, who partnered with Not Impossible Labs, Daniel is one of the first amputees in South Sudan to receive a prosthetic arm built by a consumer-grade 3D printer. Since not all 3D printers can cut metal, EDM shaped the necessary metal pieces. Not Impossible Labs creates low-cost prosthetic limbs that are known for being simple to use and affordable for anyone who needs one. Daniel is only one of more than 50,000 amputees in South Sudan whose story we have heard. Not Impossible Labs is creating better opportunities for thousands of people everyday with help from 3D printing and electrical discharge machines.

Daniel Omar Photograph: Not Impossible Labs

Sinker EDM: WET Advanced

WET is a manufacturing company based out of Sun Valley, California that designs some of the world’s most iconic fountains known to man. In order to create the specific molds required to transform a mediocre fountain into an art piece and music show, they must have EDM technology. WET is responsible for the Dancing Fountains of Bellagio in Las Vegas; as well as the 35 acre fountain in Dubai that greets the guests of the tallest building in the world known as Burj Khalifa. WET also accomplished the making of a water wall called Luminous, located in Guangzhou, China. It’s more than three stories tall and has 5,000+ LED lights. WET is using EDM in-house to make the specifically detailed P20 mold inserts required to make their sensational fountains possible. In house EDM cuts production time from six or more weeks down to two or less.

Dubai Fountain, Burj Khalifa. Image: Merek Kijevsk

Small Hole EDM Drilling: Valve lifters

Valve lifters are common and critical components in internal combustion car engines because they help regulate the opening and closing of valves. Small hole EDM drilling is used to make these valve lifters and make sure the valves in the engines are working properly. They use oil pressure to adjust their points of contact with the camshaft. Oil flows through hydraulic lifters using small hole EDM drilling.

Randy Pobst Words, Manufacturer PhotosAugust, 201

Sources:

https://www.techspex.com/knowledgecenter/guide-to-buying-machine-tools/buying-a-wire-edm