What is a Heat Sink?

Essentially every mechanical and electronic device generates some measure of heat, such as: cell phones, computers, refrigerators, disc players, microprocessors, cars, and many others. Over time this heat causes internal (and sometimes external) damage and eventually breaks down the device all together. Without cooling, these devices’ components are susceptible to cracking, melting, and short circuiting. Heat sinks are specialized heat exchangers that use the laws of thermodynamics to remove waste heat from these devices. Heat sinks come in a huge range of shapes, sizes, layouts, and compositions. However, the basic concept remains the same across the board.

How do Heat Sinks Work?

There are many different thermal and physical forces at work around a heat sink. Let’s take a closer look.

The Forces at Play

Heat Transfer

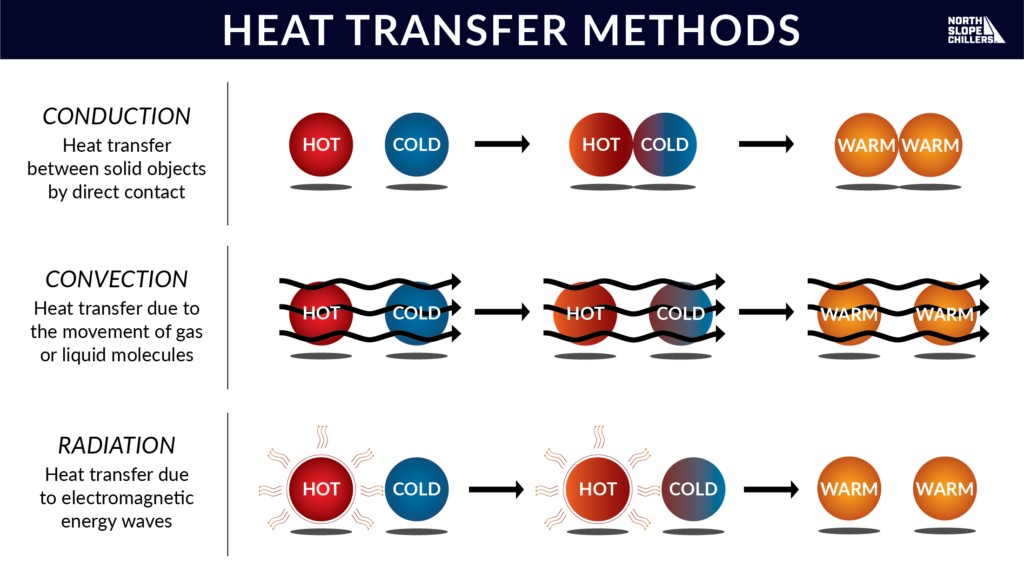

To find out how heat sinks work, we need to cover a basic knowledge of how heat is transferred from 1 object to another.

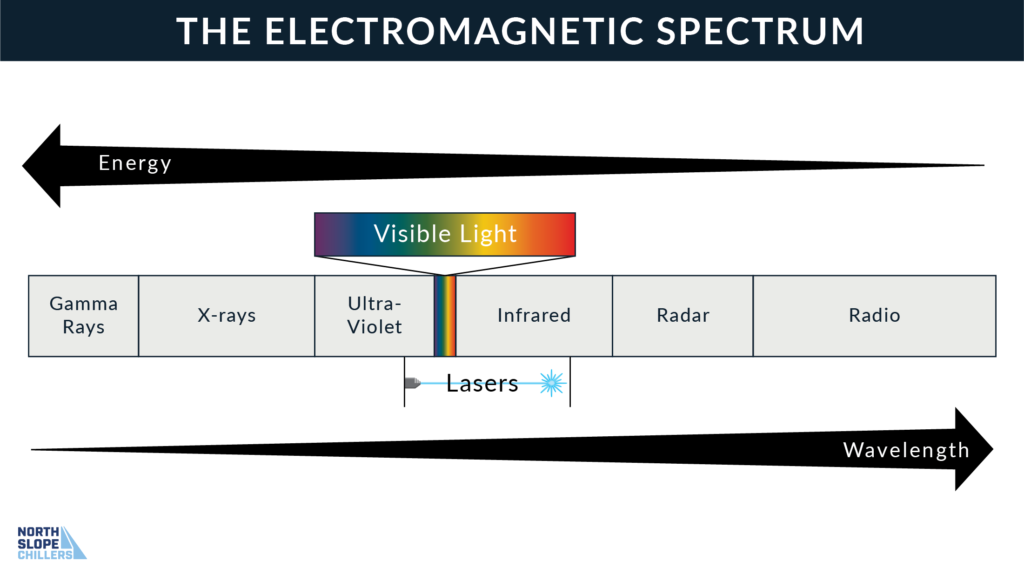

There are 3 different ways that heat can move from 1 object to another: conduction, convection, and radiation. Conduction requires physical contact between solid objects in order for heat to move. An easy example would be setting a pot on top of an electric stove. Heat is directly transferred from the stove into the surface of the pan.

Now to see convection in action, imagine you fill the pot with water. Heat will circulate and move through the liquid molecules so that even the water molecules in the center of the pot get hotter. The easiest way to understand the process of radiation is to walk outside into the sunshine. Electromagnetic waves from the sun are radiating down on us every day.

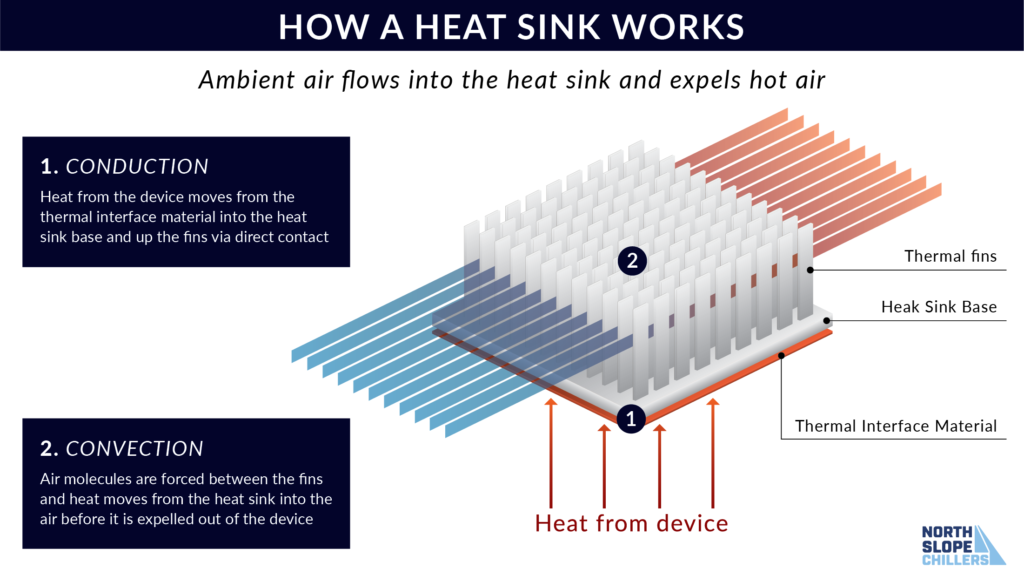

Heat sinks primarily use conduction and convection to remove unwanted heat. Heat generated by the device is piped or captured by a layer of thermal interface material. This thermal layer must eliminate all the spaces under the heat sink base, even miniscule ones due to surface roughness. Conduction relies upon direct contact, so more complete coverage = more effective heat transfer.

Fin Design and Layout

The greater the surface area of a heat sink, the more efficiently it will dissipate heat. There really are an infinite number of ways a heat sink can be designed; as a result, they come in all shapes and sizes. The size of the fins, their layout, their shape, and orientation all play a factor. Engineers will design a heat sink’s shape and layout based upon the heat load of the device in question.

Heat Sink Materials

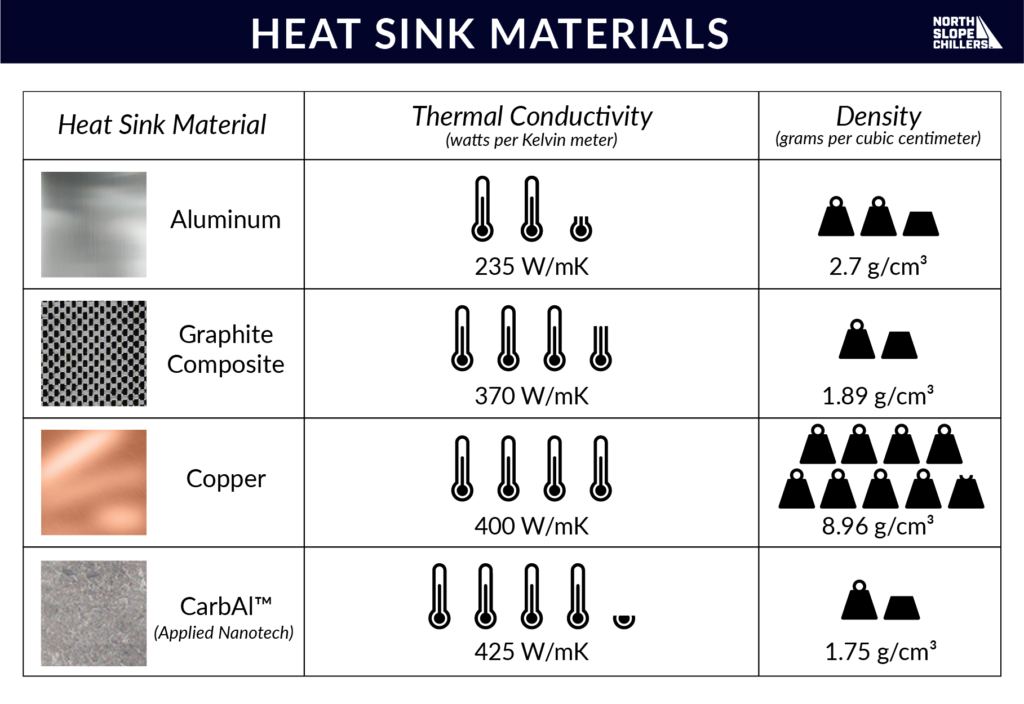

There are multiple factors to consider when choosing a heat sink material. First and foremost, is the material’s ability to transfer heat (thermal conductivity), density, and of course cost. Heat sinks are typically made from aluminum or copper. Both metals are very thermally conductive and transfer heat efficiently. Copper however is denser than aluminum, and for some devices (like cell phones), weight absolutely matters.

Some heat sink manufacturers are crafting woven graphite composite models that are extremely light and conductive. In the last several years, a new proprietary material called CarbAl™ was created by Applied Nanotech Inc. Lighter than aluminum and highly conductive, it has become a valued heat sink material for specialized devices and is even used by NASA.

Heat Sink Applications

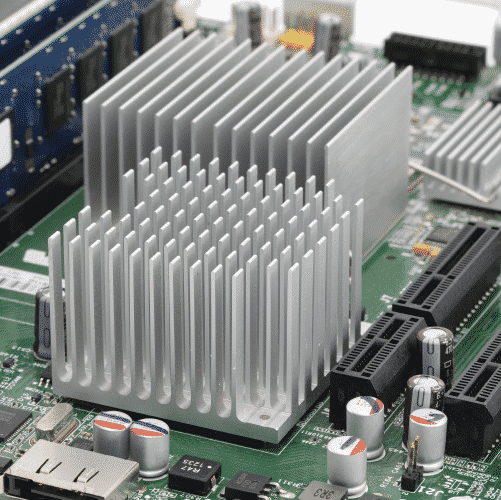

Processors

Heat sinks are most commonly used on processors. They can greatly vary in size, depending upon the device, from large all the way down to nano/micro heat sinks. Depending upon the heat load, some heat sinks will be liquid cooled because liquids can absorb and expel heat more effectively than air. High performance computers, data centers, and server farms will frequently combine heat sinks with liquid cooling to keep their large banks of equipment running cooler and more quietly. For added chilling power, these sites can also use a water/glycol mixture instead of ordinary water.

Soldering

Manufacturers sometimes install temporary heat sinks as they solder circuit boards. Soldering irons generate an extreme amount of heat. As we know through conduction, that heat will transfer to materials on the board and damage nearby sensitive electronic components. Installing a temporary heat sink will allow the solderer to work without compromising the surrounding circuit board.

Vehicles

Heat sinks are used in multiple locations on modern vehicles: oil coolers, radiators, electronics, transmission coolers, lithium batteries…basically any place that is susceptible to waste heat. Each vehicular heat sink will look different and be manufactured with its specific task in mind.

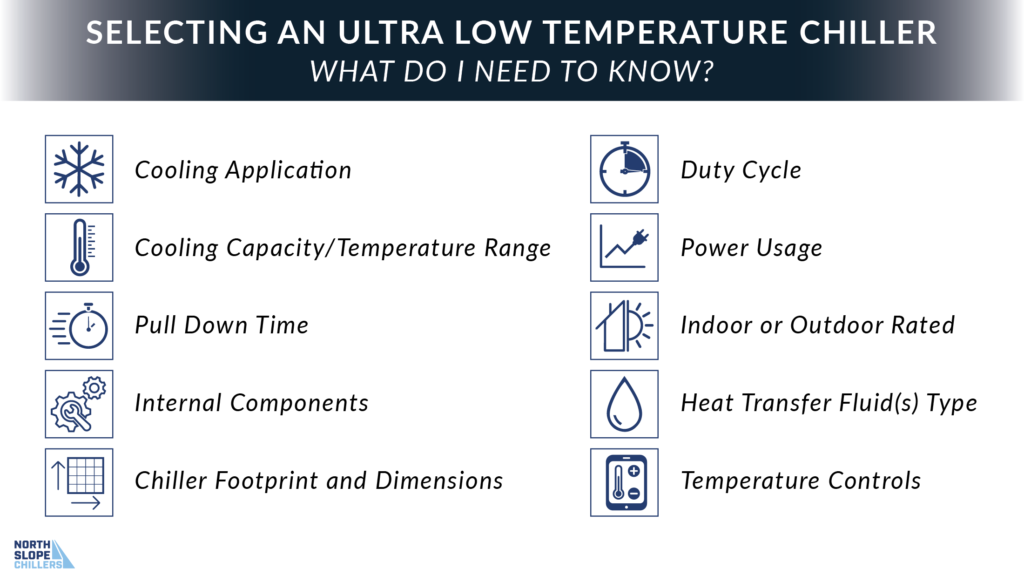

Heat Sink Cooling

When it comes to keeping devices cool, the heat sink is only half of the equation. The other half involves process cooling, or removing the waste heat. For the majority of cases, this will involve using either air or liquid.

Air Process Cooling

Some devices are equipped with internal fans to force air across and through the heat sink. For some instances, that fan will sufficiently expel heat away from the device. Larger or more complicated devices that have to work harder and longer will need additional process cooling power. For example, a single run-of-the-mill computer processor in your home office will have a built in internal fan that will automatically turn on when needed.

On the flip side, for a bank of processors in an office building or lab, that are running complex programs or high end graphics cards for long periods of time, more heavy duty process cooling is essential. In these cases, installing an industrial air cooled chiller will help protect valuable equipment and keep devices running safely and smoothly.

Liquid Process Cooling

To boost your cooling power even more, liquid cooling is the answer. Liquid (either water or a water glycol mix) absorbs heat more efficiently than air. Using an industrial liquid cooled chiller can provide you with added peace of mind that your equipment, devices, and machinery will be able to keep operating without heat damage or malfunction.

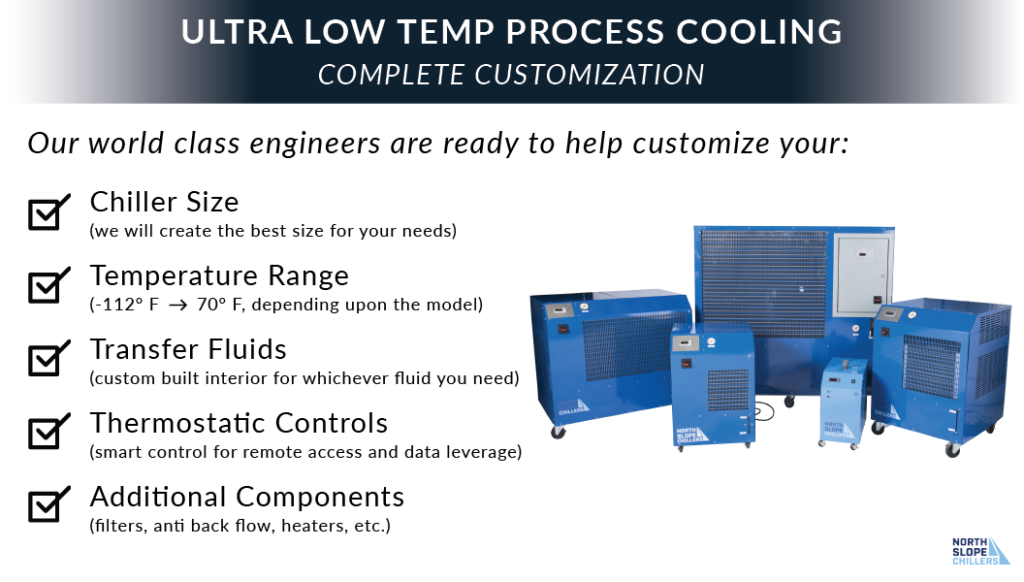

North Slope Chillers Heat Sink Cooling Solutions

Partner your hard working heat sink with efficient and powerful process cooling. Here at North Slope Chillers, our industrial chillers are portable and easily installed without disrupting the layout of your current setup. With a wide range of chiller sizes, temperature ranges, and cooling options, you can keep your equipment cool and running happily.

We also specialize in fast custom cooling solutions that can be designed to meet your exact cooling needs. Contact us today to find the right process cooling partner at (866) 826-2993 [email protected]