Riding the “Cold Chain”

As food products make their way from farm to table, they travel a path that is fraught with danger. As they are processed, packaged, distributed, and sold they are susceptible to spoilage, pathogen growth, and other contamination. Let’s follow food’s journey and find out what systems are in place to make sure it safely reaches our plates.

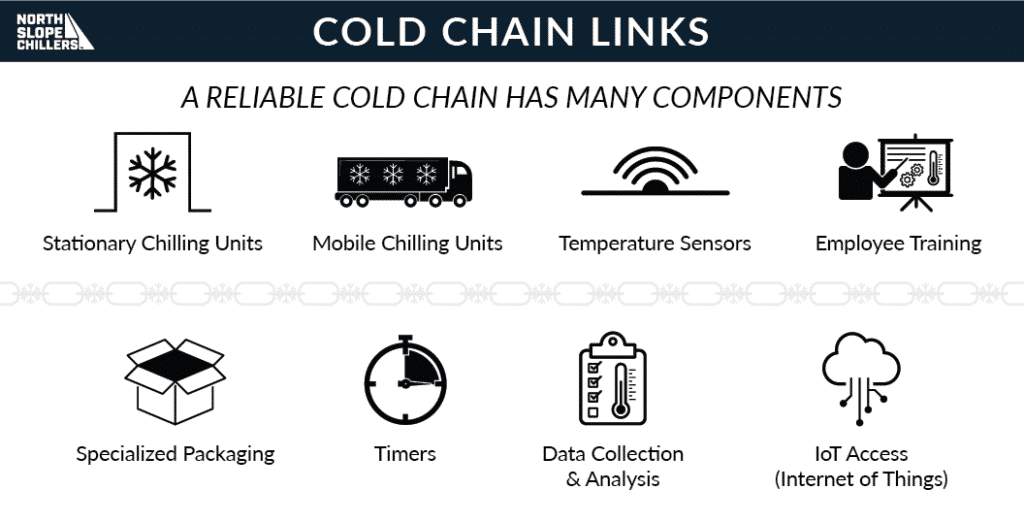

The Cold Chain

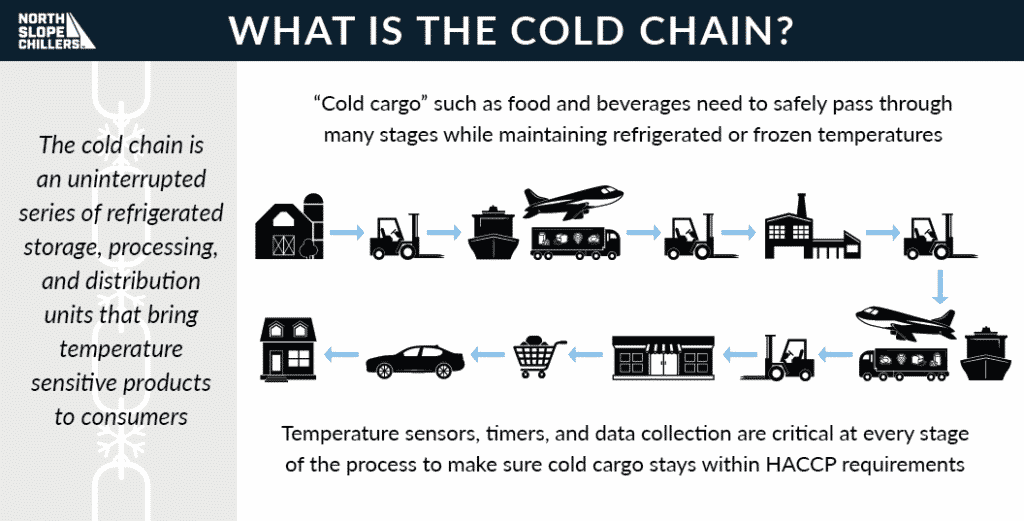

The cold chain is a series of refrigeration units that protect food along its journey. This chain is comprised of stationary and mobile cooling units as well as a network of data sensors. 1 broken link in this chain causes destructive product loss, endangers consumers, and results in expensive product recalls.

Stationary Cooling

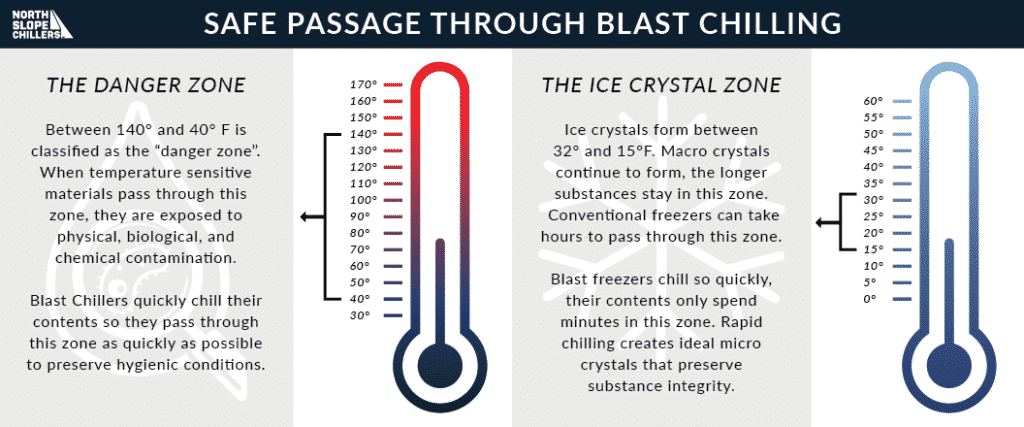

Blast chilling and blast freezing is a critical early step in food processing. Roller coaster temperatures are very damaging to food products so once food is chilled, it needs to remain that way until it is consumed. Large open space cold rooms provide food with a safe place to wait for transportation. These rooms are often large enough for food products to be packaged, reorganized, and consolidated while remaining chilled. Some cold rooms are large enough for loading machinery, such as fork-lifts, to enter and exit.

Mobile Cooling

The most complicated sections of the cold chain involve cold cargo on the move. Once food products leave the cold room, they need to be quickly loaded into a mobile refrigeration unit. These units include refrigerated trucks, reefers (ships with chilled cargo bays), refrigerated rail cars, cold air cargo planes, or a combination. Mobile chilling units need to be equipped with enough cooling power to make sure food can endure a potentially long journey.

As reliable cold chains are becoming more common, consumers are able to enjoy food products from farther and farther away. It is becoming easier for food to traverse continents, oceans, and hemispheres and still retain freshness. Once chilled food arrives at its destination, it needs to be quickly unloaded back into stationary cooling environments such as walk in fridges and freezers at restaurants, grocery stores, etc.

Managing the Cold Chain

Specialized Packaging

Shipping cold cargo can be a tricky endeavor. Cold cargo must be packaged for thermal and light protection. Reflective outer layers can be used to reduce solar temperature increases while food is being moved outside on loading docks and ramps. Specially insulated storage containers compartmentalize foods according to their temperature and humidity needs. Packaging can also have compartments to hold ice, or other chilling liquids until the food reaches a stationary cooling room.

Temperature Sensors

The most reliable cold chains have a network of temperature sensors on stationary units, mobile units, and even on the packaging itself to ensure that food is preserved the entire length of the journey.

Employee Training

Workers all throughout the cold chain need to be well trained in HACCP food handling guidelines. This ensures that workers use the most efficient food handling practices to keep food out of the contamination danger zone.

Timers

State of the art sensors can also keep track of how long packages of food have spent in each of the cold chain stages. This information can be very helpful for companies that are looking to tighten up their chain and keep food fresher for longer.

Data Collection & Analysis

Temperature, timing, and mapping data can be collected and analyzed for weak points. Previous generations needed to have workers out in the field to monitor this data, whereas now all these control points can be monitored digitally. There are many cold chain data analysis apps available that streamline cold cargo processing. It is now simpler than ever to catch food processing problems in real time before costly mistakes arise.

Internet of Things

The IoT is making waves in the food processing industry by allowing machines, sensors, and process cooling systems to all transfer data and communicate with each other without human to human or human to computer interaction. “Skynet” fears aside, this network of tech to tech communication is working hard to keep our food safer.

The Global Cold Chain

Cold Cargo in Developing Countries

The cold chain enables developing countries to more fully participate in global trade as both food producers and food consumers. Uninterrupted cold chains provide greater food variety and freshness that historically was only available to persons of higher socio-economic status. One of the fastest ways to improve the quality of life in developing areas is to provide access to fresher and healthier food options.

A reliable cold chain also creates jobs in the food manufacturing, food processing, food transportation, and food preservation industries. Post harvest losses are very detrimental to local, national, and global economies. High food spoilage rates hurt every industry involved and with a rapidly growing world population, it is even more critical that food safely reaches consumers in a timely manner.

In 2017, the Indian Food Processing Minister Harsimrat Kaur Badal cited a study that revealed startling statistics. She said, in India “hardly 10% of the horticulture produce is processed or reaches cold storages.” India is now conducting a nationwide push to create a national cold food grid to reduce post-harvest losses, create jobs, increase agricultural incomes, and provide their citizens with a greater variety of fresh, healthy food.

Environmental Concerns

Global climate change has a tremendous impact on cold cargo both in developed and developing nations. As worldwide temperatures rise, we need even more reliable cold chains extending around the globe.

Reducing food waste will help us get the most from the agricultural lands we already have, and cut back the need to hastily acquire more. By optimizing our cold chains, we can control agricultural expansion into wildlife habitats. We are currently watching vast areas of the Amazon rain forest become engulfed in flames. This is largely due to intentionally set fires to prepare more farmland to feed increasing populations.

By strengthening the global cold chain, we can greatly reduce the amount of food waste happening every year. And by so doing, we can scale back the need for hasty and destructive agricultural expansion.

Cold Chain Solutions From North Slope Chillers

Our portable industrial fluid chillers can efficiently cool loads of all shapes and sizes. They are compact, easy to install or relocate, and won’t interrupt the layout of your current system.

Contact us to find the right food chilling solution for your needs:

(866) 826-2993 [email protected]