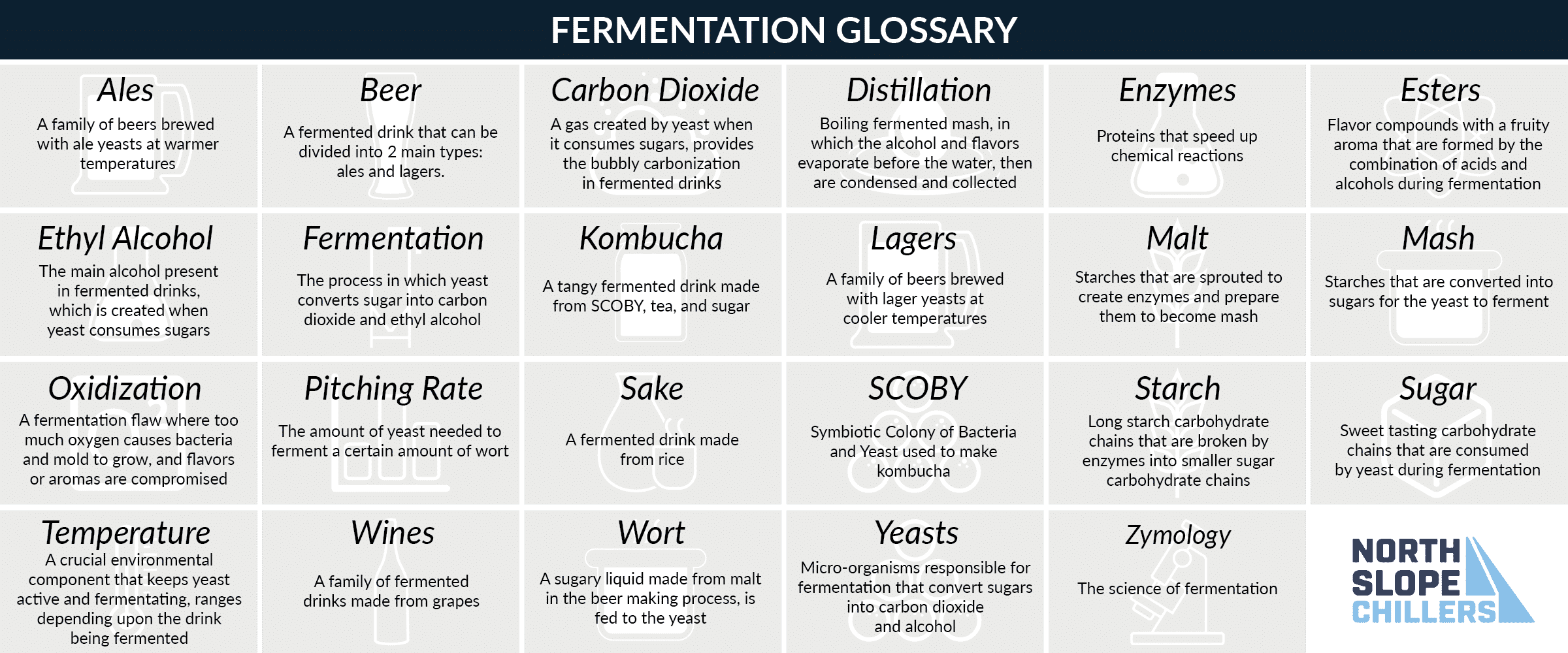

A Scientific Art

The chemical process of fermentation is relatively consistent no matter what is being fermented: starches are converted into sugars, sugars are consumed by yeast, and at certain temperatures yeast will create alcohol and carbon dioxide. While the science of fermentation may be the same, the art of fermentation creates a bouquet of flavors, aromas, colors, and alcohol levels. The art and science of fermentation uses a language all of its own.

Types of Fermented Drinks

Beer

There are 2 main families of beer: ales and lagers. The type of yeast culture and the fermentation temperature affects whether a beer becomes an ale or a lager. Ales are fermented at higher temperatures and lagers are fermented at cooler temperatures. Flavors and aromas are cultivated by a variety of starches that are malted, mashed, and then fermented within their respective temperature ranges. Those specific temperature ranges preserve the colors, flavors, and aromas enjoyed in a well-brewed beer.

Wine

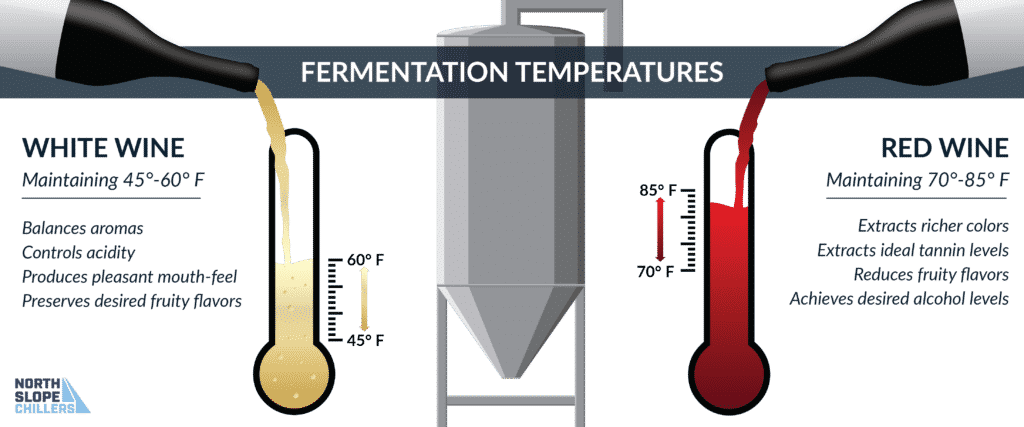

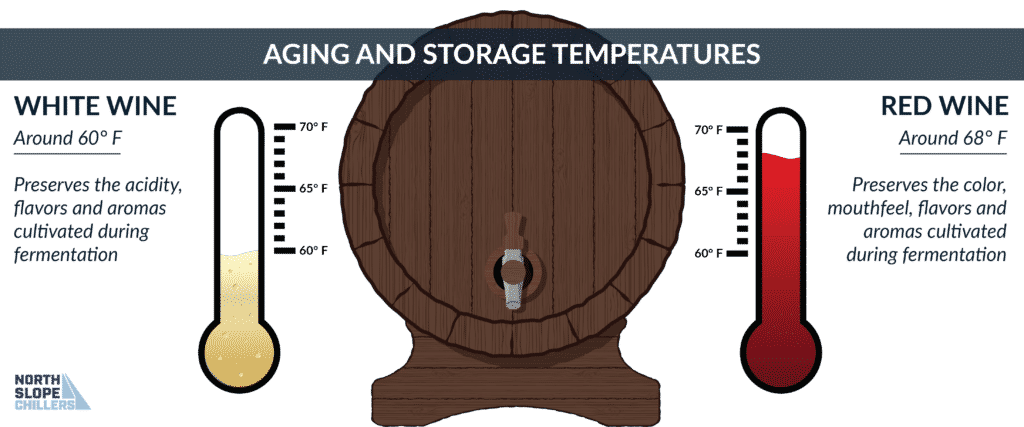

Grapes provide the sugar supply for the fermentation process of wine-making. White wines are fermented at cooler temperatures while red wines are fermented at warmer temperatures. These temperature ranges preserve, color, acidity, tannin levels, and the flavors expected of each family of wines.

Sake

Calling sake “rice wine” is a bit of a misnomer. The rice grains used to ferment sake are more like the starches in beer making, and must be converted from starch to sugar before being fermented. The sugars that feed wine yeast naturally exist in the grapes. Sake fermentation should occur at lower temperatures to slow the fermentation process.

Spirits

For clear fermented drinks, distillation must be used. The fermented mash is boiled and the flavor infused alcohols evaporate before the water, and are condensed in another vessel.

Kombucha

Kombucha is a fermented drink of SCOBY, tea, sugar, and yeast. Other ingredients such as ginger and fruit can be added to change flavors, acids, and aromas. Maintaining warm fermentation temperatures keeps acid levels steady, reduces mold growth, and encourages yeast activity.

Yeast’s Happy Place

For all these fermented drinks, fermentation is triggered by a happy, comfortable environment for yeast to grow. Temperature is the most important component in this environment and must be carefully maintained.

Put total temperature control at your fingertips for every drink you ferment. Fermentation chillers and Fluxwraps from North Slope Chillers keep your fermentation environment happy and healthy.

Contact us to find the right fermentation temperature solution for your needs at (866) 826-2993 or by email at [email protected].